Top 10 Mistakes to Avoid in Reaction Vessel Design

Designing a reaction vessel is one of the most critical steps in chemical processing. A well-designed vessel ensures process efficiency, operational safety, cost-effectiveness, and regulatory compliance. However, even experienced engineers and manufacturers can fall into common traps that lead to operational failures, poor yields, or even catastrophic accidents.

This article will highlight the Top 10 most common mistakes made during reaction vessel design, helping process engineers, procurement teams, and plant managers make more informed decisions. Whether you’re working in pharmaceuticals, petrochemicals, resins, or specialty chemicals, avoiding these errors can significantly impact your plant’s performance and profitability.

1. Ignoring the Nature of the Chemical Reaction

Failing to evaluate whether a reaction is exothermic, endothermic, or involves hazardous by-products can lead to selecting the wrong type of vessel or agitation system.

Why it matters:

Exothermic reactions need quick heat dissipation to prevent runaway reactions.

Endothermic reactions require effective heat input and retention.

Reactions with flammable or corrosive chemicals may require specialized linings like glass or PTFE.

How to avoid it:

Conduct a thorough reaction profile including thermodynamics, material compatibility, and phase behavior before vessel selection.

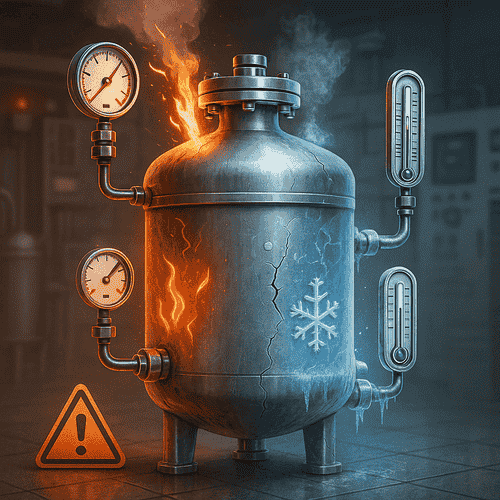

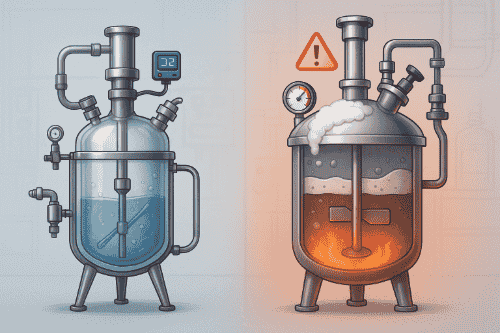

2. Overlooking Pressure & Temperature Ranges

A common oversight is underestimating the maximum operating pressure and temperature. This leads to vessels that can’t handle process extremes.

Why it matters:

Pressure surges can rupture the vessel.

High temperatures may weaken welds or seals.

Material fatigue over time can lead to stress cracking.

Solution:

Always consider design pressure + 10-20% margin. Perform finite element analysis (FEA) for high-pressure/high-temperature conditions.

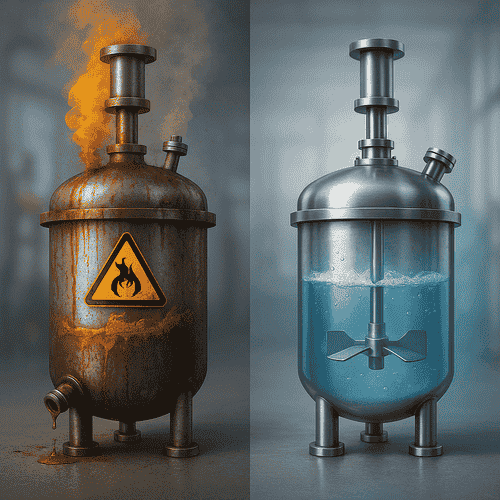

3. Incorrect Material of Construction (MOC)

Choosing the wrong MOC leads to corrosion, contamination, and premature failure of the equipment.

Common MOC Mistakes:

Using SS304 for acidic or saline processes instead of SS316 or Hastelloy.

Avoiding glass-lining when handling reactive halides or strong acids.

Pro Tip:

Match MOC with a chemical compatibility chart and always verify the concentration and temperature conditions.

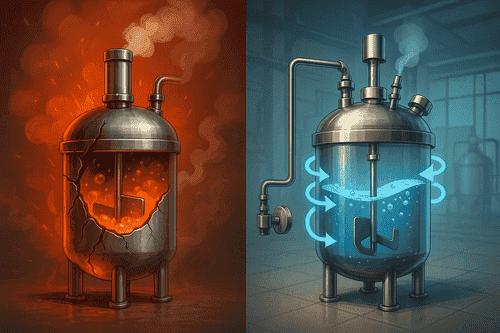

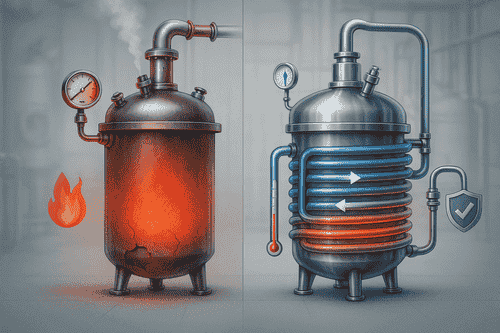

4. Improper Heat Transfer System Selection

A poorly designed heating or cooling system leads to temperature fluctuations and batch inconsistencies.

Mistakes to watch for:

Choosing a jacketed vessel when a limpet coil is better suited for higher-pressure fluids.

Incorrect placement of inlet/outlet ports for heating media.

Insufficient surface area for heat exchange.

Fix it:

Use thermal simulation tools to model the process heat flow. Consider baffle plates or dimple jackets for enhanced efficiency.

5. Inadequate Agitation System

Not all reactions require the same mixing mechanism. Poor agitation design results in dead zones, inefficient mass transfer, or shear damage to sensitive compounds.

Types of common agitators:

Anchor (for high-viscosity materials)

Turbine (for turbulent flow)

Contra-rotating (for complex blending)

Magnetic stirrer (for sterile/GMP environments)

Avoid this by:

Consulting a mechanical engineer to perform mixing time and power number calculations before deciding on the impeller type.

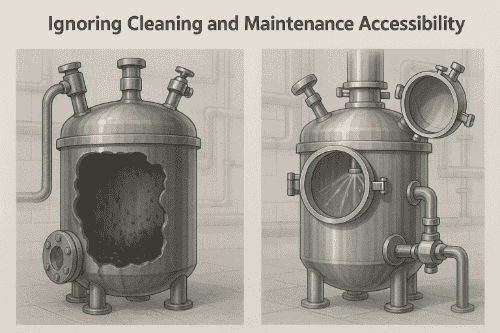

6. Ignoring Cleaning and Maintenance Accessibility

Designs that don’t incorporate CIP (Clean-in-Place) or easy-access nozzles often lead to operational delays and contamination risks.

Key issues:

Inaccessible sampling ports.

No manway or inspection glass.

Lack of drain slope at the vessel bottom.

Design tip:

Ensure compliance with GMP and 5S principles. Always include sloped bottoms and strategically placed spray balls or rotary jets.

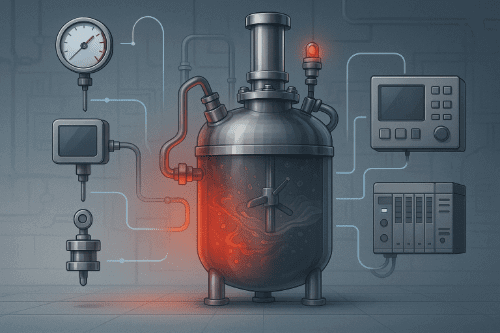

7. Neglecting Instrumentation and Control Integration

Without proper instrumentation, real-time monitoring and automation are not feasible.

Common missing elements:

Temperature and pressure transmitters.

pH or conductivity sensors.

Load cells for weight monitoring.

Solution:

Integrate digital sensors and control panels into the vessel skid. Plan for DCS or SCADA integration at the design stage.

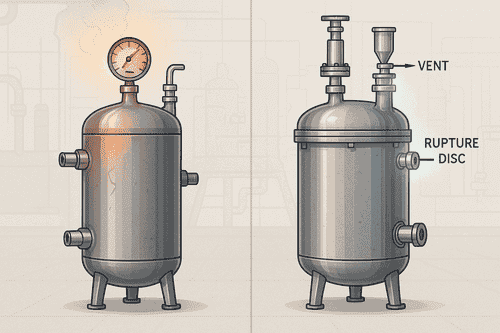

8. Overlooking Venting, Safety Valves & Rupture Discs

Every closed system must have pressure relief mechanisms. Omitting this is a serious safety risk.

You must include:

Pressure Relief Valves (PRV)

Rupture discs

Vacuum breakers (especially for cooling)

Best practice:

Design relief systems according to API 520/521 standards. Factor in reaction exothermicity when sizing vent lines.

9. Scale-Up Miscalculations

Lab-scale vessels don’t always translate directly to pilot or production scale. Ignoring scale-up dynamics results in yield issues and equipment failures.

Why scale-up fails:

Surface-to-volume ratio changes

Agitation doesn’t scale linearly

Heat transfer becomes inefficient

How to fix it:

Use dimensional analysis and computational fluid dynamics (CFD) modeling to validate scale-up parameters.

10. Not Considering Future Expansion or Flexibility

Designing a vessel only for current batch size and chemical formulation without future-proofing can lead to rework and CAPEX loss.

What to include:

Modular nozzle flanges

Extra ports for future automation

Reinforced structure for optional pressure upgrades

Pro Tip:

Build 20–30% volume flexibility and include documentation for expansion compatibility.

Designing a reaction vessel is not just a mechanical engineering task—it’s a multidisciplinary process that balances chemistry, safety, and operations. Avoiding the mistakes listed above can save your company from costly retrofits, downtime, compliance issues, or worse—hazards that threaten life and environment.

At Liuminex Projects and Equipments, we help our clients avoid these pitfalls by offering custom-engineered reaction vessels built to exact process requirements with full testing, certifications, and after-sales support.