Reaction Vessel ( Reactor )

High-Performance Stainless Steel Reaction Vessel

At Liuminex, we manufacture high-quality Stainless Steel Reaction Vessel (Chemical Reactor) designed for efficient mixing, chemical reactions, polymerization, and heat transfer processes. Our vessels are engineered to meet the demanding requirements of industries such as chemicals, pharmaceuticals, petrochemicals, resins, paints, lubricants, and food processing. Whether you need a batch reactor, jacketed vessel, pressure reactor, or agitator-equipped vessel, we provide customized solutions to match your exact process needs.

Key Features of Our Stainless Steel Reaction Vessel

- Capacities from 50 Litres to 50,000 Litres

- Material options: Stainless Steel (SS 304, SS 316), Mild Steel (MS), Alloy Steel, Hastelloy

- Designs: Jacketed, Limpet Coil, Pressure-rated

- Agitator types: Anchor, Turbine, Helical, High-shear

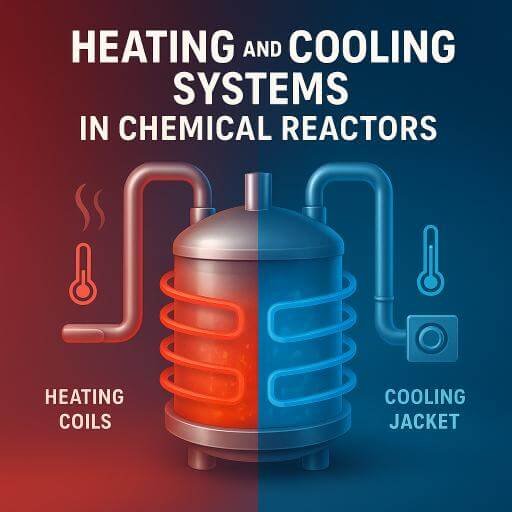

- Heating/Cooling: Steam, Hot Oil, Electric, Chilled Water

- Compliance with ASME, GMP, IS, and DIN standards

- CIP/SIP ready, where applicable

- Explosion-proof motors and control systems available

Technical Specifications of Stainless Steel Reaction Vessel

Parameter | Specification |

Design Pressure | Up to 25 bar |

Design Temperature | Up to 300°C |

Mounting | Vertical / Horizontal / Skid-mounted |

Surface Finish | Mirror finish / Matt finish / Electro-polished |

Agitator Speed | Variable (VFD controlled), 10–300 RPM |

Sealing | Mechanical Seal / Gland Packing |

Nozzles | Inlet, Outlet, Vent, Manhole, Thermowell, etc. |

Insulation | Glass wool / Mineral wool (optional) |

Applications

Our Stainless steel reaction vessel are used in a wide range of processes:

🔹 Polymerization and condensation reactions

🔹 Blending of viscous liquids

🔹 Preparation of resins, adhesives, dyes

🔹 Pharmaceutical and biotech fermentation

🔹 Saponification and chemical neutralization

🔹 Heat-sensitive material processing

Types of Reaction Vessels We Offer

Provides dual heating/cooling zones for better control of exothermic/endothermic reactions.

For efficient indirect heating or cooling. Ideal for temperature-sensitive reactions.

Why Choose Us?

- 10+ years of experience in process equipment manufacturing

- In-house design and fabrication with CNC precision

- Fully customizable to suit your specific process

- On-time delivery and installation support

- Supplied across India, Middle East, Africa, and Southeast Asia

Limpet Coil Reaction Vessel

Premium Limpet Coil Reactors for Efficient Heating & Cooling

We specialize in manufacturing Limpet Coil Reaction Vessels that offer precise temperature control during exothermic and endothermic reactions. Designed to meet industrial standards, these reactors are ideal for chemical, pharmaceutical, paint, resin, adhesive, and petrochemical industries.

Our vessels are custom-engineered for batch or continuous operations, with single or double limpet coils for steam, hot oil, or chilled water circulation.

Key Features of Limpet Coil Stainless Steel Reaction Vessel

- ✅ Available Capacities: 100 Litres to 50,000 Litres

- ✅ Material Options: SS 304, SS 316, MS, Hastelloy, Alloy 20

- ✅ Single / Double Coil Options

- ✅ External and Internal Coils (for heating and cooling)

- ✅ Steam / Oil / Glycol circulation

- ✅ Agitator with mechanical seal and VFD

- ✅ High-pressure design up to 25 bar

- ✅ Compliance: ASME / GMP / IS / DIN standards

Technical Specifications

Parameter | Specification |

Capacity Range | 100L – 50,000L |

Design Pressure | Up to 25 kg/cm² |

Temperature Range | -20°C to 300°C |

MOC | SS 304, SS 316, MS, Alloy Steel |

Coil Thickness | 3 mm to 12 mm |

Heating Media | Steam, Thermic Fluid, Hot Oil |

Cooling Media | Water, Chilled Water, Brine |

Agitator Type | Anchor / Paddle / Turbine / Helical |

Advantages of Limpet Coil Reactors

🔹 Efficient heat transfer without contamination of the process material

🔹 Separate zones for heating and cooling

🔹 Easy to clean and maintain

🔹 Ideal for viscous or sensitive materials

🔹 Strong mechanical design for high-pressure operations

Applications of Limpet Coil Reactors

- Polymerization and resin synthesis

- Dye and pigment manufacturing

- Lube oil blending and grease processing

- Pharmaceutical reactions

- Chemical mixing and neutralization

Design Customizations Available

- Double limpet coil (dual service – heating/cooling)

- Bottom discharge with flush valves

- Flameproof motor and gearbox

- Automation-ready with PLC/SCADA integration

- Load cells and level sensors for batch control

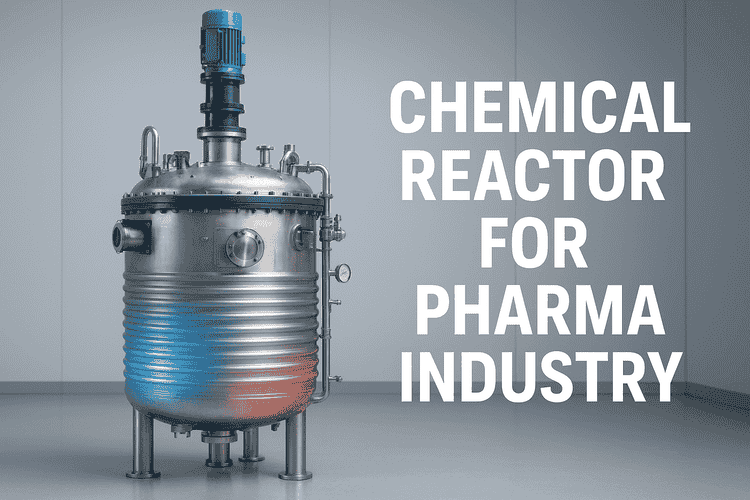

Jacketed Reaction Vessel

Engineered Jacketed Reactors for Optimal Thermal Control

We manufacture robust and highly efficient Jacketed Reaction Vessels designed for controlled heating or cooling of materials during chemical reactions. These vessels are widely used in chemical, pharmaceutical, food, resin, and petrochemical industries, where process temperature regulation is critical.

Our jacketed reactors are available in custom capacities and materials, and can be built to ASME, GMP, and international standards.

What is a Jacketed Reaction Vessel?

A jacketed reactor is a pressure-rated vessel equipped with an external jacket (or layer) through which steam, hot oil, or chilled water can be circulated. This allows for indirect and uniform heating or cooling of the internal batch without direct contact with the heating medium, ensuring product purity and process safety.

Key Features

✅ Capacities: 50 Litres to 50,000 Litres

✅ Materials of Construction: SS 304, SS 316, MS, Hastelloy, Alloy 20

✅ Jacket Types: Dimple jacket, Conventional jacket, Half-pipe coil

✅ Heating Media: Steam, Thermic Fluid, Hot Water

✅ Cooling Media: Chilled Water, Brine

✅ Pressure Design: Up to 25 bar

✅ Temperature Range: -20°C to 300°C

✅ Compliance: ASME / IS / DIN / GMP certified

Technical Specifications

| Parameter | Specification |

| Design Pressure | Up to 25 kg/cm² |

| Jacket Pressure Rating | 3–10 bar (customizable) |

| MOC (Shell & Jacket) | SS 304, SS 316, MS, Hastelloy |

| Agitator Type | Anchor / Paddle / Turbine / Helical / Magnetic |

| Surface Finish | Mirror / Matt / Electro-Polished |

| Mounting | Skid-mounted / Leg-supported / Platform-based |

| Nozzles Provided | Inlet, Outlet, Manhole, Thermowell, Vent, etc. |

Advantages of Jacketed Reaction Vessels

🔹 Precise thermal control for temperature-sensitive processes

🔹 Safe and clean operation with indirect heat exchange

🔹 Ideal for batch, semi-batch, and continuous processing

🔹 Compatible with automation and process control systems

🔹 Reduces risk of product degradation or contamination

Applications

- Resin production (alkyd, epoxy, polyester)

- Pharmaceutical reactions and formulation

- Chemical blending and synthesis

- Food processing (syrups, concentrates)

- Adhesives and emulsions

- Paints and pigments

Optional Add-ons

- Flameproof motor & VFD-controlled agitator

- Load cell system for batch weighing

- SCADA/PLC-based automation

- Pressure safety valves & rupture discs

- Insulation with aluminum/GI cladding

- CIP/SIP compatible (for GMP environments)

Pressure Reaction Vessel

Designed for Safe & Efficient High-Pressure Reactions

We manufacture Pressure Reaction Vessels engineered for handling elevated pressure and temperature during critical reactions such as hydrogenation, polymerization, alkylation, and catalytic processing. Designed to meet ASME, DIN, or GMP standards, these vessels are built with robust materials, flawless welding, and stringent safety features.

Applications

- Hydrogenation

- Catalytic reactions

- Polymerization

- Nitration / Sulfonation

- High-pressure batch synthesis

- Oil refining and petrochemical reactions

Key Features

- Pressure rating up to 20 bar (customizable per requirement)

- Construction in SS304, SS316, SS316L, Hastelloy, Inconel, or Alloy 20

- Jacketed or limpet coil for heating and cooling (steam/oil/water)

- ASME/PED certified designs with necessary documentation

- Agitator options: Anchor, turbine, helical, or magnetic drive

- Thermal control system with PT100 sensors, temperature & pressure gauges

- Pressure safety devices: rupture discs, PRVs, flame arrestors

- Instrumentation: Load cell, PLC-based automation, digital pressure control

- CIP/SIP ready for pharmaceutical-grade applications

Technical Specifications

Parameter | Specification |

Capacity | 50 – 50,000 Litres |

Design Pressure | Up to 20 bar |

Design Temperature | Up to 350°C |

Agitation System | Mechanical / Magnetic / VFD driven |

Heating/Cooling | Jacketed / Limpet Coil / Electric / Steam |

Material of Construction | SS304, SS316, SS316L, Hastelloy, Inconel |

Mounting Type | Skid-mounted / Leg-supported |

Certification | ASME Sec VIII Div 1, PED, GMP, ISO 9001 |

Customization Options

- Magnetic seal drive for leakage-free operation

- Flameproof motor and control panel (ATEX / IECEx)

- Load cell integration for weight monitoring

- Spray ball for internal CIP cleaning

- SCADA/PLC-controlled automation

- Glass sight glass with wiper and light

- Gas inlet nozzles and pressure regulation manifold

Industries Served

- Specialty Chemicals & Intermediates

- Pharmaceutical API & Intermediates

- Petrochemical & Refining

- Agrochemical Manufacturing

- Adhesives & Polymers

- R&D and Pilot Plants

Agitated Reaction Vessel

Precision Mixing for Controlled Chemical Reactions

Liuminex manufactures high-performance Agitated Reaction Vessels designed for batch and continuous processing involving heat transfer, reaction kinetics, dispersion, or emulsification. These vessels are equipped with customized agitators to suit various viscosities, phase mixing, and temperature-sensitive reactions.

Built to GMP, ASME, and DIN standards, our reactors ensure maximum efficiency, safety, and product integrity in complex chemical or pharmaceutical processes.

Applications

- Chemical synthesis

- Pharmaceutical intermediates

- Resin and polymer production

- Emulsification and dispersion

- Heating and cooling reactions

- Acid-base neutralization

- Extraction and crystallization

Key Features

Agitator Types: Anchor, turbine, propeller, pitched blade, helical, or magnetic seal

Drive: Top-mounted geared motor with VFD speed control

Heating/Cooling: Jacketed or limpet coil design (Steam / Hot Oil / Water)

MOC: SS304 / SS316 / SS316L / Hastelloy / Alloy 20 / Carbon Steel

Pressure/Vacuum Rated: Design up to -760 mmHg vacuum or 10 bar pressure

Temperature Control: PID-based digital controllers with PT-100 sensors

CIP/SIP Ready: Mirror-polished surface and sanitary fittings for hygienic use

Automation: PLC/SCADA systems available with HMI touchscreen interface

Optional: Baffles, manholes, sight glass with light & wiper, rupture disc, load cells

Technical Specifications

Parameter | Specification |

Capacity | 100 to 50,000 Litres |

Design Pressure | Up to 10 bar (customizable) |

Design Temp. | Up to 250°C |

Agitation Speed | 10 to 150 RPM (adjustable with VFD) |

Material | SS316, SS304, Hastelloy, or customized |

Mounting | Skid / Leg Supported |

Surface Finish | Mirror Polish (Ra < 0.4 µm) / Matt / Glass Bead |

Common Agitator Configurations

Agitator Type | Best For |

Anchor | High viscosity, heat transfer fluids |

Turbine | Low/medium viscosity, gas-liquid mixing |

Propeller | Low viscosity, general mixing |

Helical | Pastes and thick emulsions |

Magnetic Seal | Leak-proof sterile applications |

Industries Served

- Chemical & Petrochemical

- Pharmaceutical APIs

- Paints & Adhesives

- Cosmetics & Personal Care

- Food Processing

- Pesticides & Agrochemicals

BLOGS

Home About Us Products Stainless Steel Reaction Vessel Heat Exchangers and Condensers Industrial Storage Tanks Ribbon Blender Plough Shear Mixer Vacuum & Solvent Receivers Rotary Vacuum Paddle Dryer (RVPD) Rotary

Home About Us Products Stainless Steel Reaction Vessel Heat Exchangers and Condensers Industrial Storage Tanks Ribbon Blender Plough Shear Mixer Vacuum & Solvent Receivers Rotary Vacuum Paddle Dryer (RVPD) Rotary

Home About Us Products Stainless Steel Reaction Vessel Heat Exchangers & Condensers Industrial Storage Tanks Ribbon Blender Plough Shear Mixer Vacuum & Solvent Receivers Rotary Vacuum Paddle Dryer (RVPD) Rotary

Home About Us Products Stainless Steel Reaction Vessel Heat Exchangers & Condensers Industrial Storage Tanks Ribbon Blender Plough Shear Mixer Vacuum & Solvent Receivers Rotary Vacuum Paddle Dryer (RVPD) Rotary

Home About Us Products Stainless Steel Reaction Vessel Heat Exchangers & Condensers Industrial Storage Tanks Ribbon Blender Plough Shear Mixer Vacuum & Solvent Receivers Rotary Vacuum Paddle Dryer (RVPD) Rotary