How to Select the Right Reaction Vessel for Your Chemical Process

Choosing the right Chemical reactor (reaction vessel) is one of the most critical decisions in any chemical manufacturing operation. Whether you’re producing pharmaceuticals, agrochemicals, resins, or polymers, the vessel in which your reaction takes place will directly affect product quality, process efficiency, and safety compliance. Liuminex is a best Chemical Reactor Manufacturers in Mumbai.

In this Chemical reactor guide, we’ll walk you through how to select the right reaction vessel based on the type of reaction, operating conditions, materials of construction, and custom process requirements.

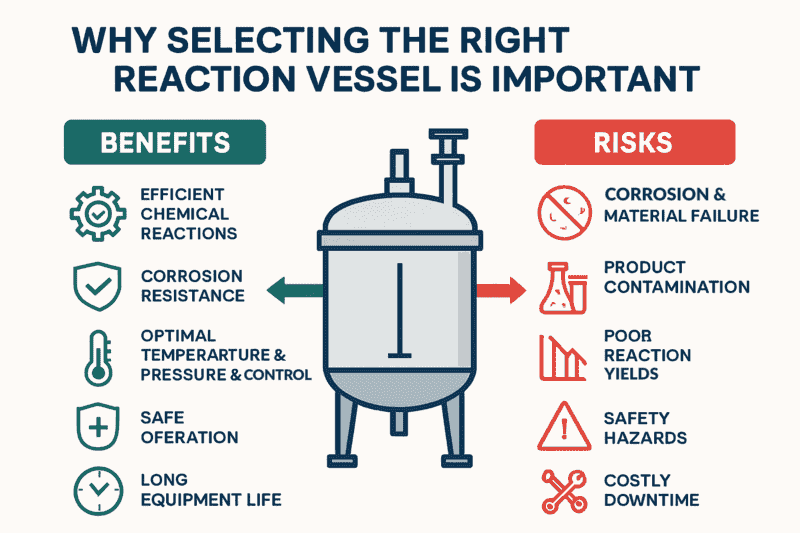

Why Is Selecting the Right Reaction Vessel So Important?

A reaction vessel isn’t just a container — it’s a high-performance engineered system designed to control:

Temperature and pressure

Chemical compatibility

Mixing dynamics

Heat exchange

Cleaning and maintenance

Using the wrong vessel can lead to:

Corrosion or material failure

Low reaction yield or inconsistent product

Increased downtime and maintenance

Safety hazards or equipment damage

Key Factors to Consider When Selecting a Chemical Reactor

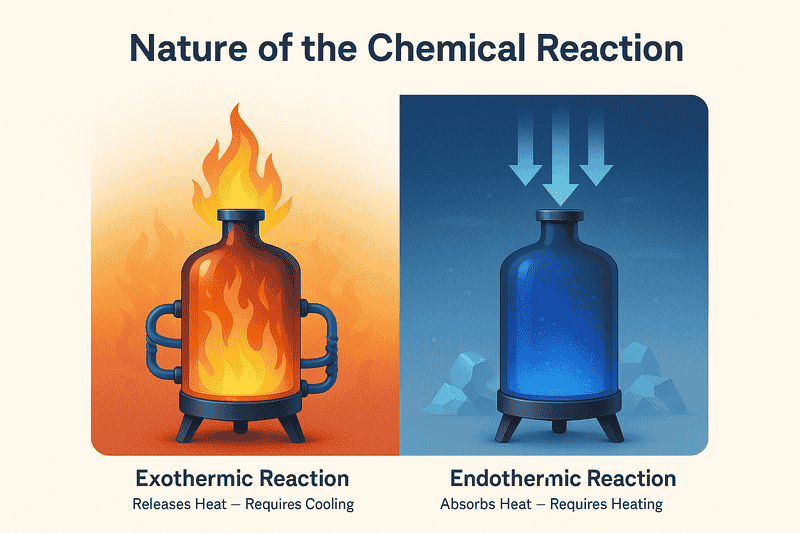

1. Nature of the Chemical Reaction

1. Is the reaction exothermic or endothermic?

Exothermic Reactions release heat during the process. These reactions can lead to rapid temperature rise if not controlled properly.

Vessel requirement: Efficient heat removal systems such as jacketed or limpet coil vessels.

Example: Neutralization reactions, polymerization, or certain oxidation processes.

Endothermic Reactions absorb heat, requiring continuous external heating to maintain the desired reaction temperature.

Vessel requirement: Powerful heating systems using steam, thermic fluid, or electrical heating coils.

Example: Decomposition reactions, certain catalytic processes.

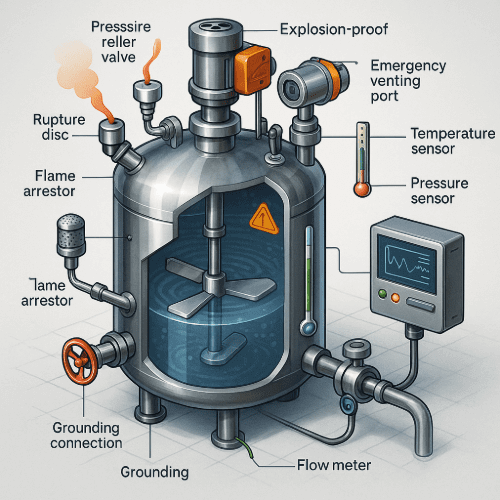

2. Are there any hazardous or flammable materials involved?

Handling hazardous, toxic, or flammable chemicals adds layers of safety and compliance requirements to your reaction vessel design.

Use flameproof motors, ATEX-certified components, and pressure safety valves.

Vessels must include emergency venting, rupture discs, and gas scrubbers where applicable.

Explosion-proof electrical enclosures are essential in flammable zones.

3.What are the by-products or reaction residues?

By-products can be:

Gaseous: May require gas scrubbing or venting systems

Liquid: Might need condensate collection or neutralization

Solid: Could cause sedimentation or clogging, requiring easy drain designs

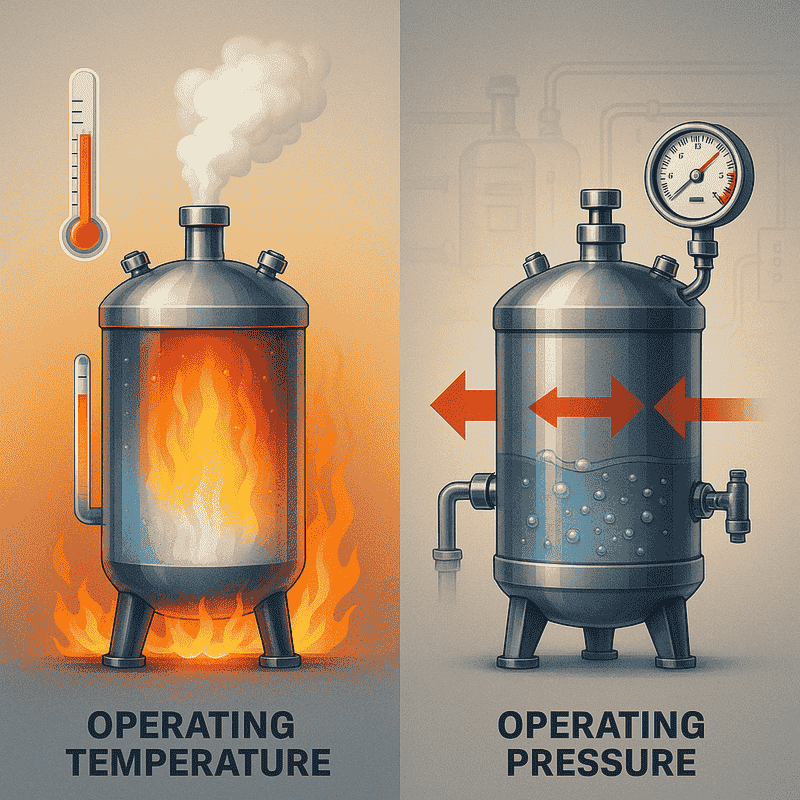

2. Operating Temperature and Pressure

| Range | Vessel Requirement |

|---|---|

| Up to 150°C | Standard SS304 or SS316 jacketed vessel |

| 150–300°C | Limpet coil or double jacketed reactor |

| Above 300°C or >10 bar | High-pressure autoclaves with ASME certification |

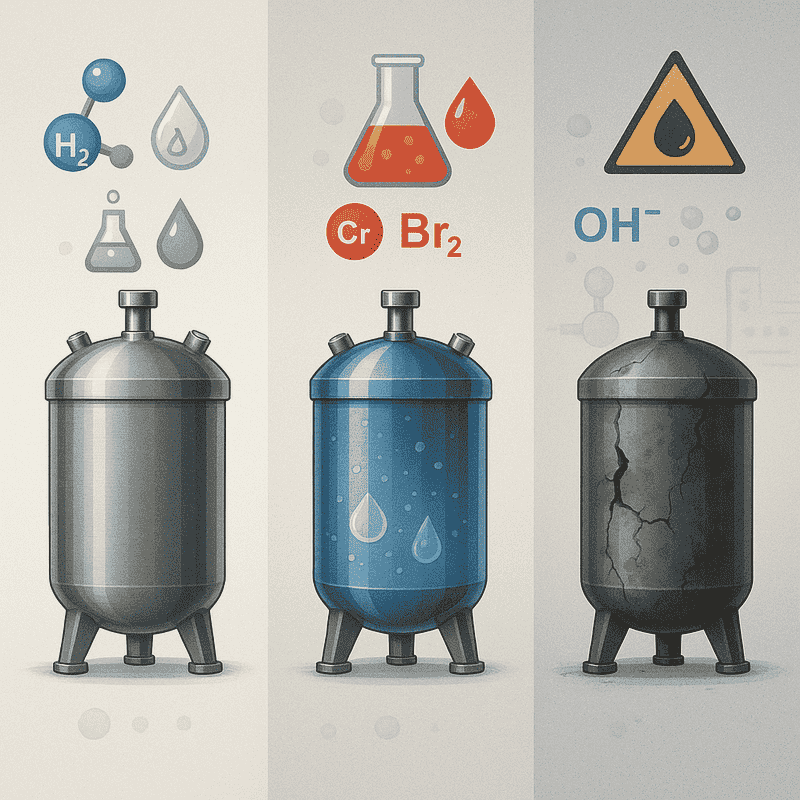

3. Material Compatibility

Choose the material of construction (MOC) based on corrosion and pH tolerance:

| Chemical Type | Recommended Material |

|---|---|

| Acids, Chlorides | SS316L, Hastelloy C276 |

| Alkalis | Glass-lined or PTFE-coated vessels |

| Organic solvents | SS304 or SS316 |

| Oxidizers | Titanium, Hastelloy |

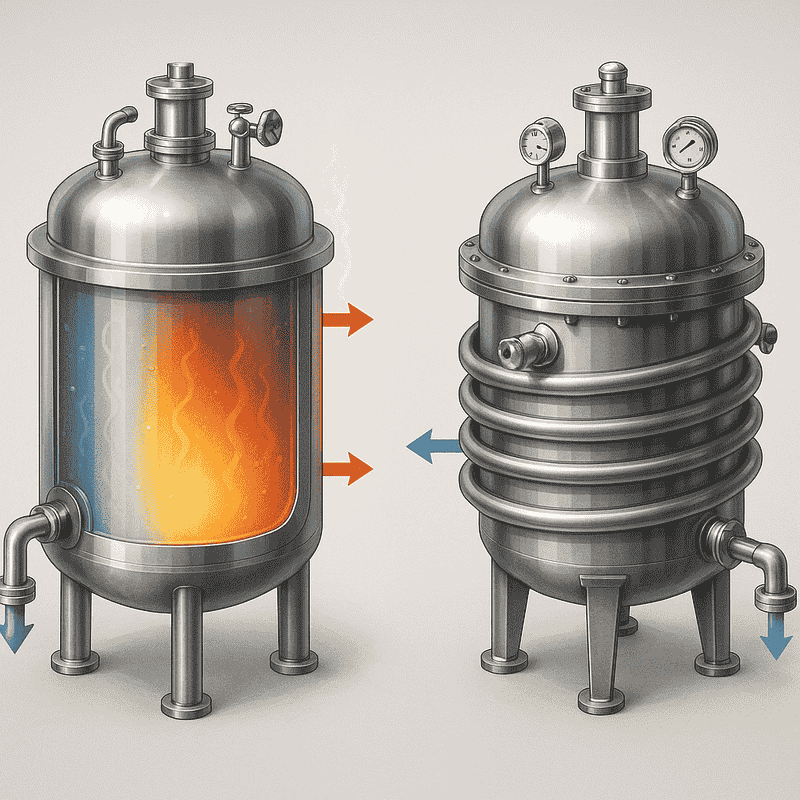

4. Vessel Configuration: Jacketed vs Limpet Coil

| Type | Benefits | Common Use |

|---|---|---|

| Jacketed | Full external shell coverage for even heating/cooling | Pharma, food, and fine chemicals |

| Limpet Coil | High-pressure handling and quick thermal transfer | Resin, paints, polymers |

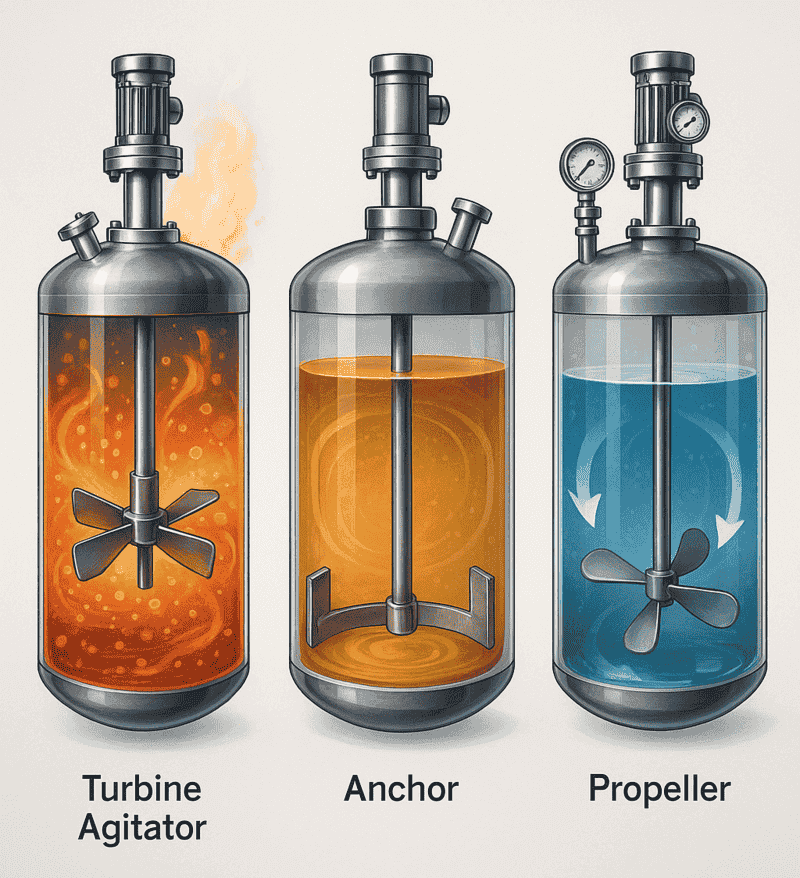

5. Agitator Design Based on Mixing Needs

Anchor Type: For viscous materials like resins and gels

Turbine or Propeller: For low-viscosity liquids

Contra-Rotating: For precision mixing in complex reactions

Bottom-Mounted Agitator: For low-clearance spaces or pharma applications

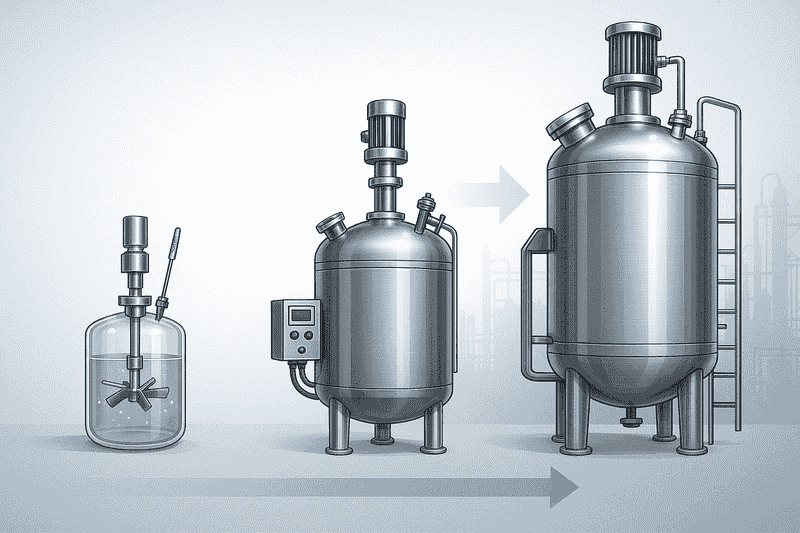

6. Reactor Volume and Scalability

Start with a pilot-scale vessel and scale up. Common volumes:

R&D: 5–50 liters

Pilot Plant: 100–500 liters

Commercial: 1,000–30,000 liters+

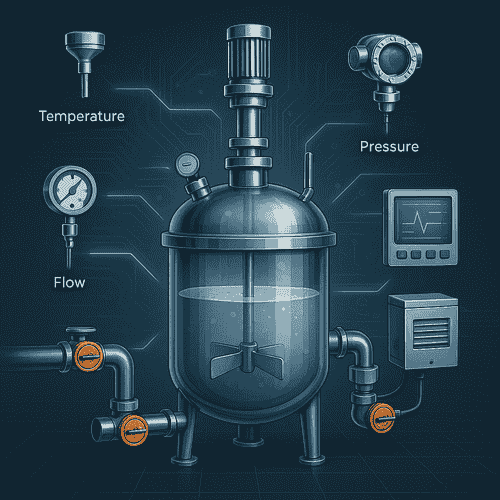

7. Automation and Instrumentation

Consider advanced features for better control:

PLC/SCADA based temperature & pressure control

Digital RPM control for agitators

Load cells for batch weighing

Level and pressure sensors

8. Safety Features to Look for in a Reaction Vessel

Safety is non-negotiable when handling high-pressure, high-temperature, or hazardous chemical reactions. A well-designed reaction vessel should include built-in features that prevent accidents and support emergency protocols.

Must-Have Safety Features:

Pressure Relief Valves (PRVs)

Rupture Discs

Level Indicators

Temperature and Pressure Sensors

Emergency Shutoff Valves

Flameproof Motors and Panels

Grounding Lugs to prevent static buildup

Manways with locking safety systems

9. Cost Considerations & Return on Investment (ROI)

While selecting a reaction vessel, cost is always a factor—but the lowest cost is not always the best value. It’s important to balance initial investment with long-term savings in energy, efficiency, and maintenance.

Factors Affecting Cost:

Material of Construction (SS304 < SS316 < Hastelloy < Titanium)

Vessel size and thickness

Agitation complexity (fixed vs variable speed, multiple agitators)

Heating/Cooling requirements

Automation level (manual vs PLC-controlled)

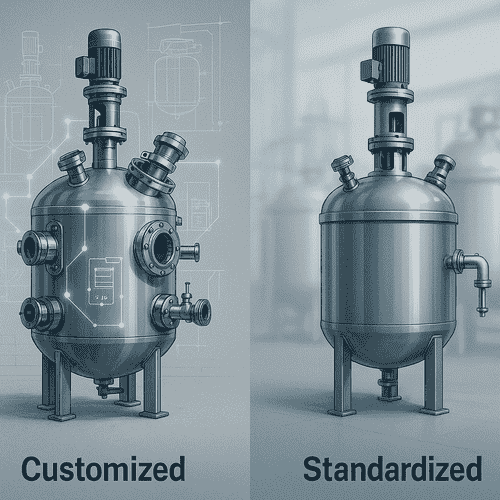

10. Customization vs. Standardized Vessels

While off-the-shelf vessels may be cost-effective for general use, most industrial processes benefit from customized solutions. A custom reaction vessel allows optimization for:

Batch size and frequency

Viscosity and flow patterns

Thermal requirements

Multi-product compatibility

At Liuminex, we offer both standard models and fully customized systems, engineered to match your exact process requirements and plant layout.

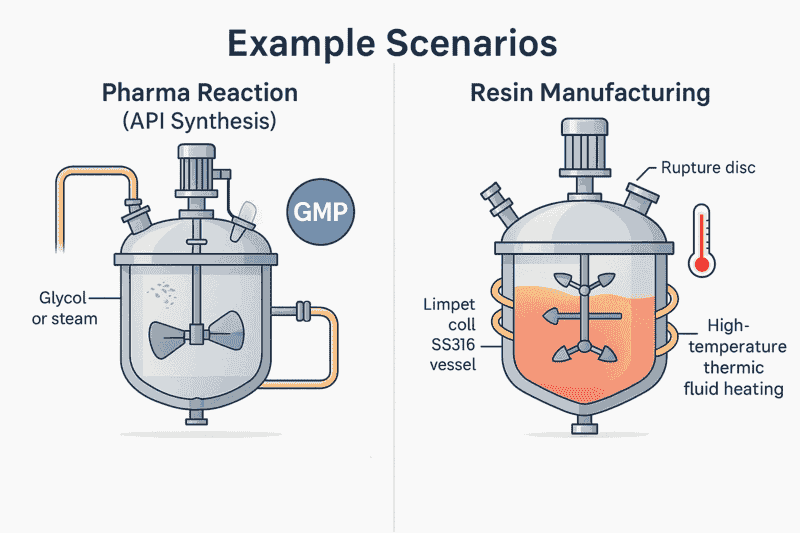

Example Scenarios

Pharma Reaction (API Synthesis):

-

Jacketed heating with glycol or steam

-

Anchor agitator with baffles

-

GMP-compliant with CIP system

Resin Manufacturing:

Limpet coil SS316 vessel

Contra agitator

High-temperature thermic fluid heating

Manual sampling port and rupture disc

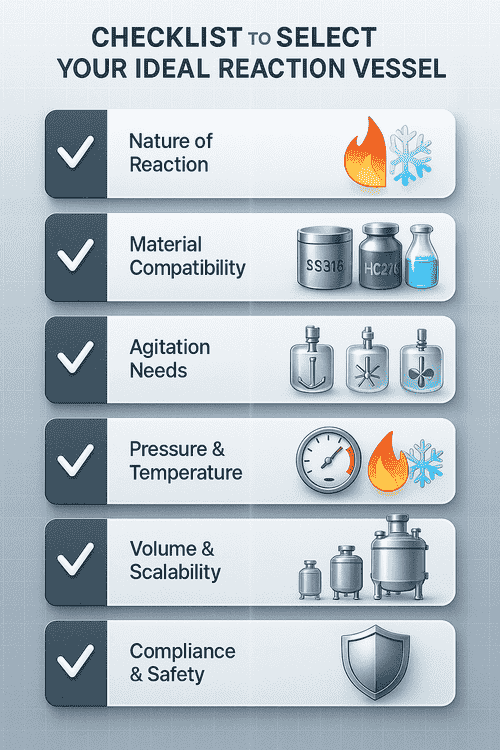

Checklist to Select Your Ideal Reaction Vessel

- Identify reaction type and chemical compatibility

- Define temperature and pressure range

- Select suitable MOC (SS304/SS316/Hastelloy/Glass-lined)

- Choose vessel type (Jacketed or Limpet)

- Define agitation needs (RPM, mixing type)

- Confirm volume and scalability

- Ensure instrumentation and safety compliance

- Verify design codes (ASME, IS, PED, CE)

Liuminex Reaction Vessel Solutions

At Liuminex Projects and Equipments Pvt. Ltd., we manufacture a wide range of reaction vessels tailored to industry-specific needs:

SS Jacketed Reactors (100L – 50KL)

Limpet Coil Reactors with Top Drive Agitators

Glass-Lined Reactors with PTFE Accessories

GMP & ASME-Certified High-Pressure Reactors

Fully Automated Systems with SCADA Control

Serving industries in pharmaceuticals, agrochemicals, paints, polymers, and specialty chemicals.

Final Tips Before You Select

Here’s a quick checklist to finalize your reaction vessel decision:

1. Have you defined chemical properties and hazards?

2. Did you analyze pressure, temperature, and volume ranges?

3. Have you chosen the right material of construction?

4. Are all safety and control systems specified?

5. Does your vendor provide documentation, drawings, testing, and inspection certificates?

6. Will the vessel scale with your production growth?

Why Choose Liuminex for Chemical reactor?

At Liuminex Projects and Equipments Pvt. Ltd., we don’t just build vessels—we engineer reliable chemical solutions. Here’s what makes us stand out:

1. 100% Custom-Engineered Vessels

2. In-house 3D Design & Process Simulation

3. ASME & GMP Certified Manufacturing

4. On-Time Delivery & Full Site Installation Support

5. NDT, Hydrotesting & Third-Party Inspection

6. Post-sales Training & Maintenance Support

Frequently Asked Questions (FAQs)

Q1. What is the difference between jacketed and limpet coil vessels?

Jacketed vessels offer even heating/cooling with full shell coverage. Limpet coils offer faster thermal response and handle higher pressure.

Q2. Which material is best for acid-based chemical reactions?

SS316L or Glass-Lined Steel depending on concentration and temperature.

Q3. What standards should a reaction vessel comply with?

ASME Section VIII, IS 2825, GMP, or CE depending on your industry and location.