Heat Exchangers

What Are Heat Exchangers?

Heat exchangers are critical thermal equipment used to transfer heat between two or more fluids at different temperatures without direct mixing. In chemical processing plants, they are essential for heating, cooling, condensing, evaporating, and recovering energy from process streams.

Industries looking for a reliable Heat Exchangers Manufacturer in Mumbai prefer suppliers who understand chemical process requirements, Indian operating conditions, and global quality standards.

Unlike reaction vessels where chemical transformation occurs, heat exchangers focus on energy management, ensuring that processes operate at the required temperature for safety, efficiency, and product quality.

They are used in reactor heating/cooling, distillation columns, condensers, reboilers, evaporators, and utility systems.

Importance of Heat Exchangers in Chemical Processing Plants

Heat exchangers directly influence:

Reaction rates

Product yield

Energy consumption

Plant safety

Operational costs

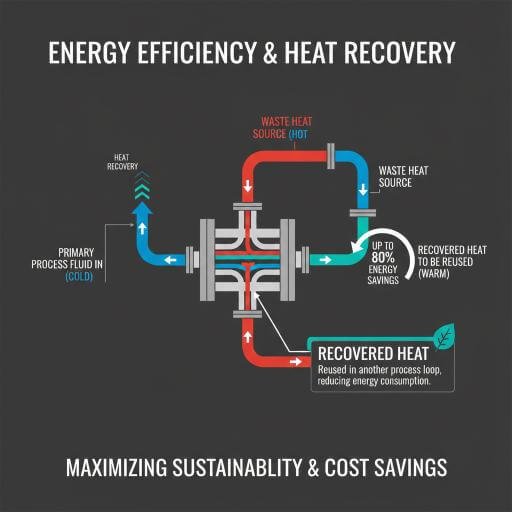

Efficient heat transfer reduces fuel usage, minimizes cooling water demand, and supports energy recovery, making heat exchangers central to sustainable plant operation.

In modern chemical plants, more than 60% of energy optimization efforts revolve around heat exchanger networks.

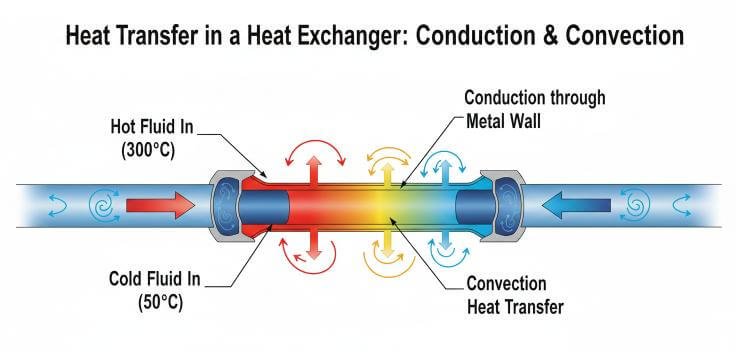

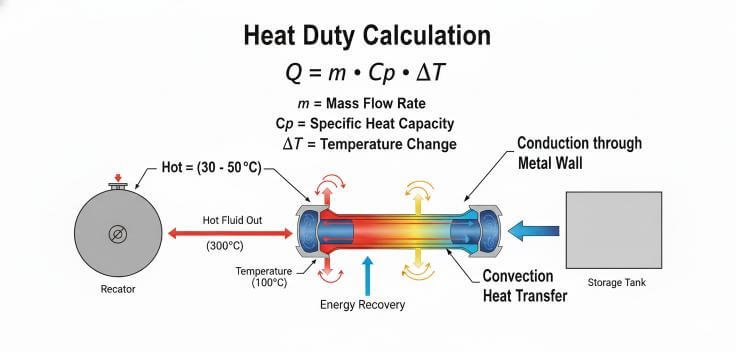

Basic Principle of Heat Transfer

Heat exchangers operate based on three fundamental heat transfer mechanisms:

Conduction: Heat transfer through solid surfaces (tube walls, plates).

Convection: Heat transfer between fluid and surface.

Radiation: Minor contribution at very high temperatures.

The driving force is the temperature difference (ΔT) between fluids. Engineers calculate heat duty using:

Q = m × Cp × ΔT

This governs exchanger sizing, surface area, and flow arrangement.

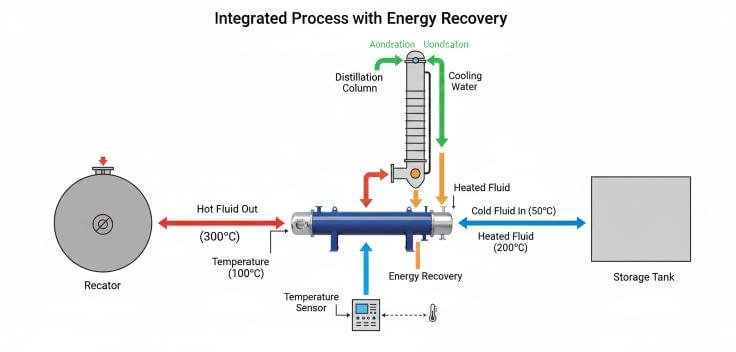

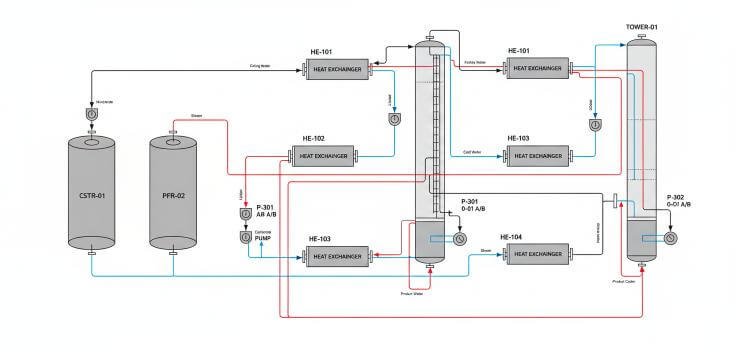

Role of Heat Exchangers in Chemical Equipment Integration

Heat exchangers do not work in isolation. They are integrated throughout the plant, supporting:

Reaction vessel temperature control

Condensation of vapors from distillation columns

Preheating feed streams

Cooling product streams before storage

Heat recovery between hot and cold process streams

This integration reduces overall energy demand and improves process stability.

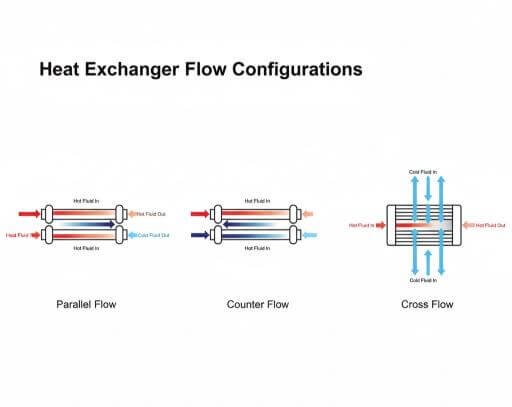

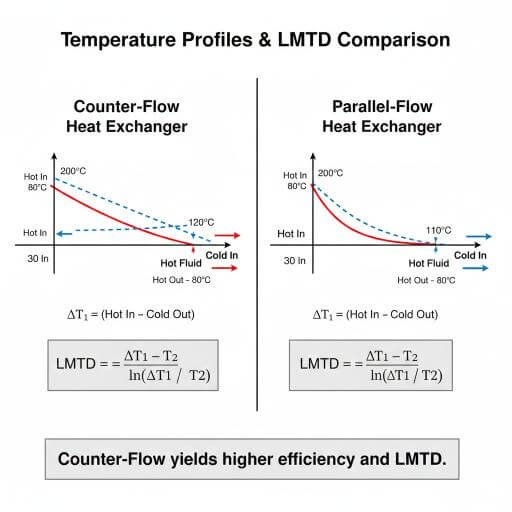

Classification of Heat Exchangers by Flow Arrangement

Based on fluid movement, heat exchangers are classified as:

Parallel Flow

Both fluids enter from the same end and flow in the same direction. Used for gentle heating or cooling.

Counter Flow

Fluids flow in opposite directions, offering maximum thermal efficiency.

Cross Flow

Fluids move perpendicular to each other, common in air coolers.

Counter-flow designs are most widely used in chemical plants due to better temperature approach.

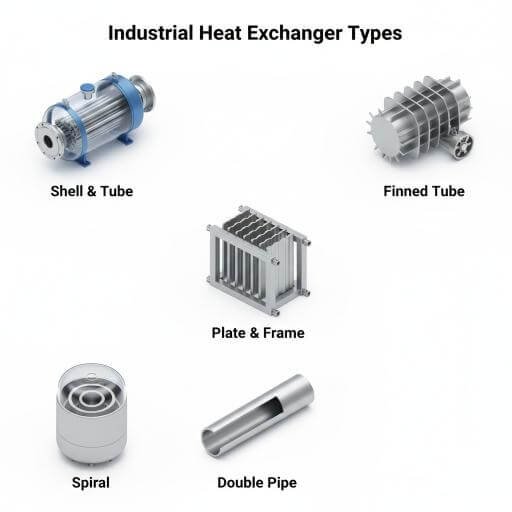

Classification by Construction Type

Heat exchangers are categorized based on mechanical design:

Shell and Tube Heat Exchangers

Plate Heat Exchangers

Air Cooled Heat Exchangers

Double Pipe Heat Exchangers

Spiral Heat Exchangers

Each design offers advantages based on pressure, temperature, fouling tendency, and maintenance needs.

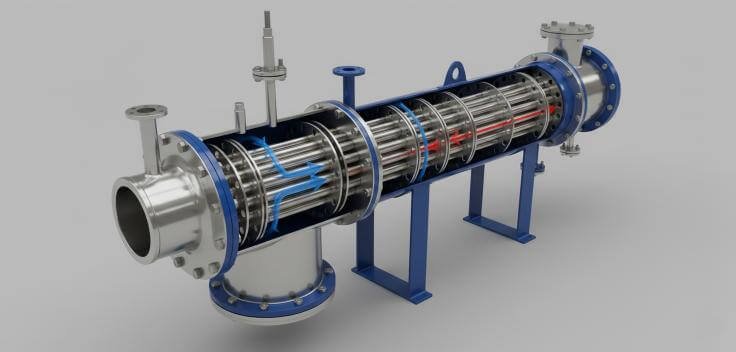

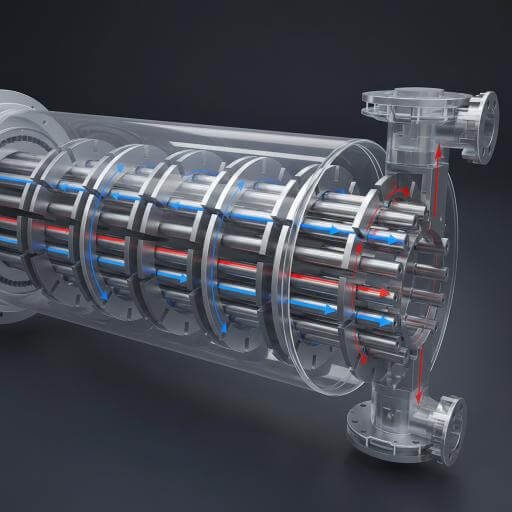

Shell and Tube Heat Exchangers – Industry Standard

Shell and tube heat exchangers are the most commonly used type in chemical processing due to their:

High pressure handling capability

Wide temperature range

Mechanical robustness

Customizable design

They consist of a bundle of tubes enclosed in a cylindrical shell, allowing one fluid to flow through tubes and the other through the shell side.

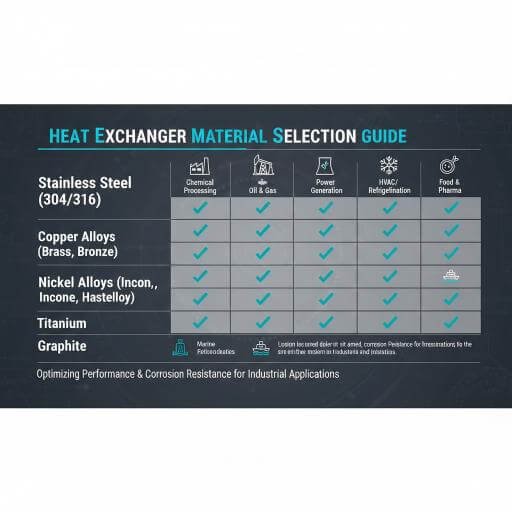

Materials Used in Heat Exchangers

Material selection is critical to prevent corrosion, fouling, and failure.

Common materials include:

Carbon Steel – cost-effective, moderate resistance

SS304 / SS316L – corrosion-resistant

Hastelloy – aggressive chemical services

Titanium – chloride resistance

Copper Alloys – excellent thermal conductivity

Material choice impacts heat transfer efficiency and service life.

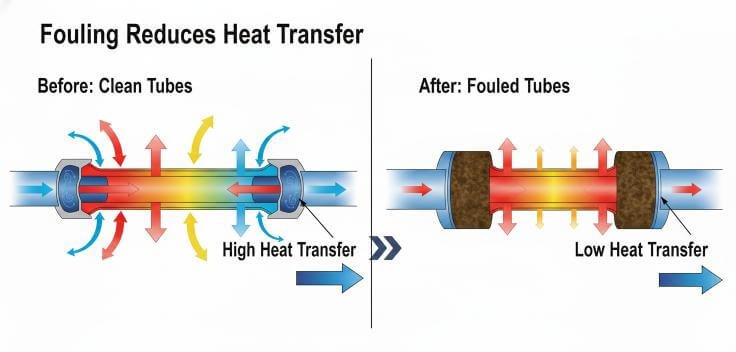

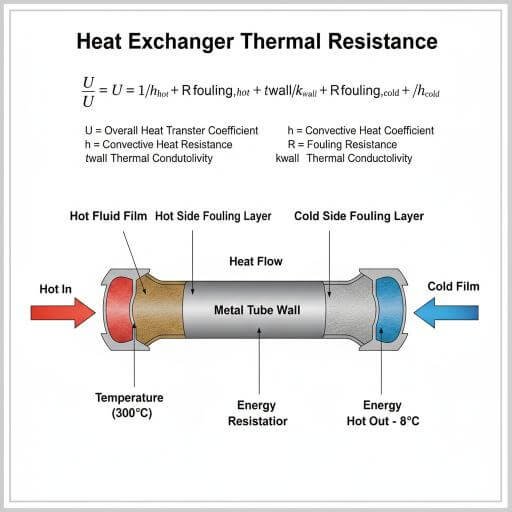

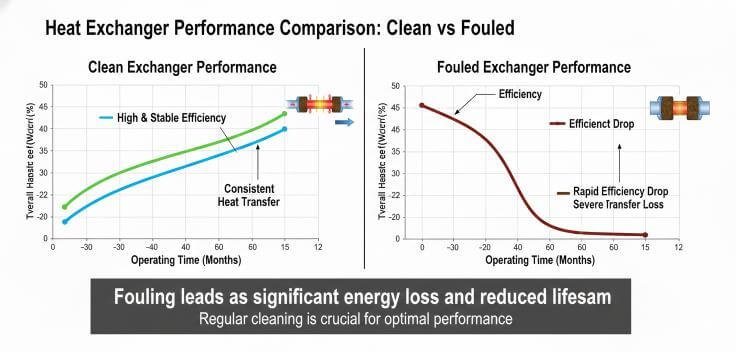

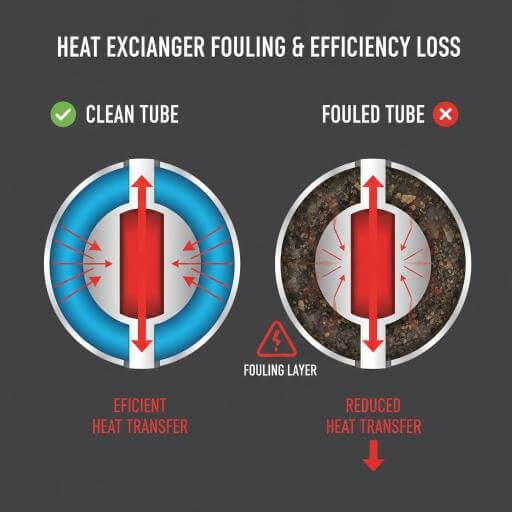

Fouling and Its Impact on Performance

Fouling occurs when deposits form on heat transfer surfaces, reducing efficiency. Common fouling types include:

Scaling

Corrosion fouling

Biological fouling

Particulate fouling

Design strategies like higher velocity, proper material selection, and easy cleaning access help minimize fouling.

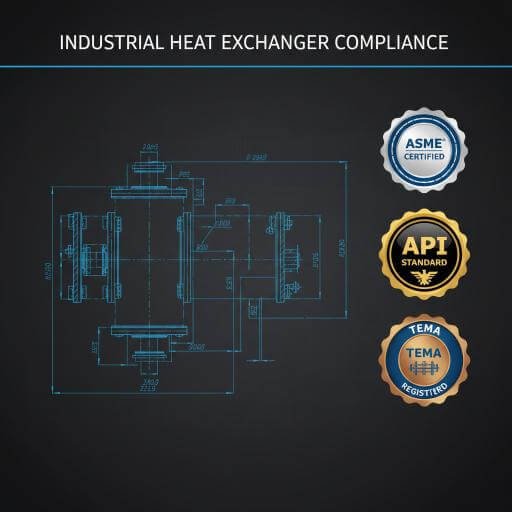

Heat Exchanger Design Standards

Industrial heat exchangers must comply with global standards:

TEMA – Mechanical design guidelines

ASME Section VIII – Pressure integrity

API 660 – Shell & tube exchangers

IS codes – Indian standards

Compliance ensures safety, reliability, and global acceptance.

Why Heat Exchangers Are Strategic Equipment

Heat exchangers directly affect:

Operating cost

Energy efficiency

Carbon footprint

Equipment lifespan

Optimized heat exchanger design can reduce plant energy usage by 20–40%, making them a strategic investment.

As a trusted Heat Exchangers Manufacturer in Mumbai, Liuminex focuses on delivering efficient, durable, and process-specific heat transfer solutions for chemical industries.

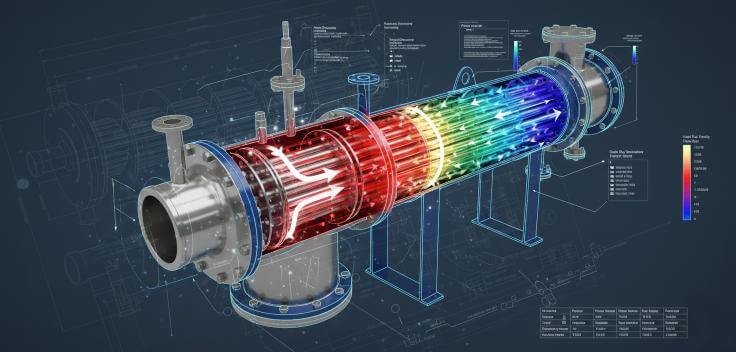

Heat Exchanger Design & Engineering Fundamentals

Why Heat Exchanger Design Is Critical

Heat exchanger design determines how efficiently energy is transferred, how safely the equipment operates, and how long it will last in a chemical plant. Poor design can result in excessive energy consumption, fouling, corrosion, pressure drop issues, and frequent shutdowns.

Unlike standard mechanical equipment, heat exchangers require simultaneous thermal, hydraulic, and mechanical optimization. Engineers must consider heat duty, fluid properties, operating conditions, and future fouling margins.

A reputed Heat Exchangers Manufacturer follows detailed thermal design calculations to ensure long-term efficiency and safe operation under demanding chemical process conditions.

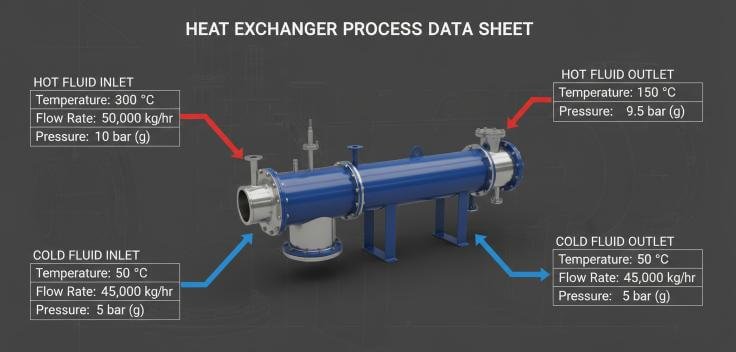

Defining Process Requirements

The first step in heat exchanger design is understanding process data. Without accurate input data, even the best mechanical design will fail.

Key process parameters include:

Hot and cold fluid inlet temperatures

Desired outlet temperatures

Flow rates (kg/hr)

Specific heat (Cp)

Density and viscosity

Allowable pressure drop

Fouling tendency

This data forms the basis for all thermal calculations.

Heat Duty Calculation

Heat duty (Q) represents the amount of heat that must be transferred. It is calculated using:

Q = m × Cp × (T₁ − T₂)

Where:

m = mass flow rate

Cp = specific heat

T₁, T₂ = inlet and outlet temperatures

Accurate heat duty ensures correct sizing of heat transfer surface area and prevents under- or over-design.

Log Mean Temperature Difference (LMTD)

LMTD represents the effective temperature driving force across the heat exchanger.

LMTD equation:

LMTD = (ΔT₁ − ΔT₂) / ln(ΔT₁ / ΔT₂)

Counter-flow exchangers have higher LMTD values, making them more efficient than parallel-flow designs.

Overall Heat Transfer Coefficient (U)

The overall heat transfer coefficient combines all thermal resistances:

Fluid film resistance

Tube wall resistance

Fouling resistance

Higher U-values indicate better heat transfer performance. Fouling factors are added conservatively to maintain long-term performance.

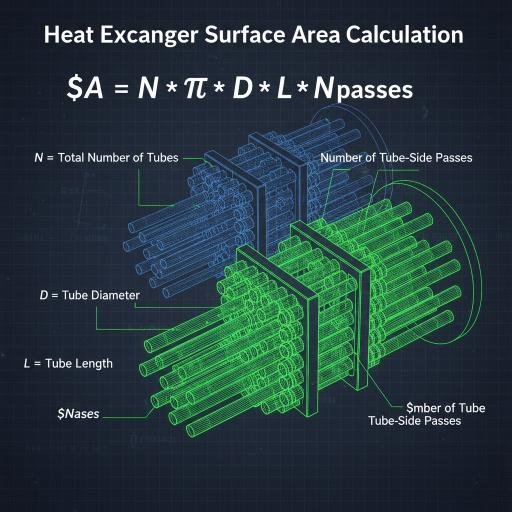

Heat Transfer Surface Area Calculation

Once Q, U, and LMTD are known, required surface area (A) is calculated using:

Q = U × A × LMTD

This determines the number of tubes, tube length, or plate size in the exchanger.

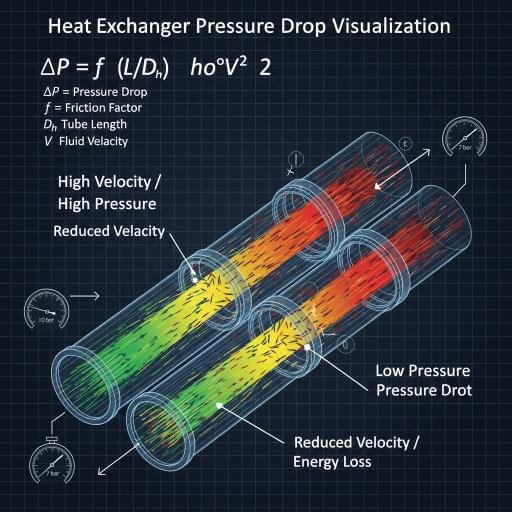

Pressure Drop Considerations

Excessive pressure drop increases pumping cost and may disrupt upstream or downstream equipment.

Designers balance:

Fluid velocity

Tube diameter

Number of passes

Baffle spacing

Chemical plants typically limit pressure drop to preserve process stability.

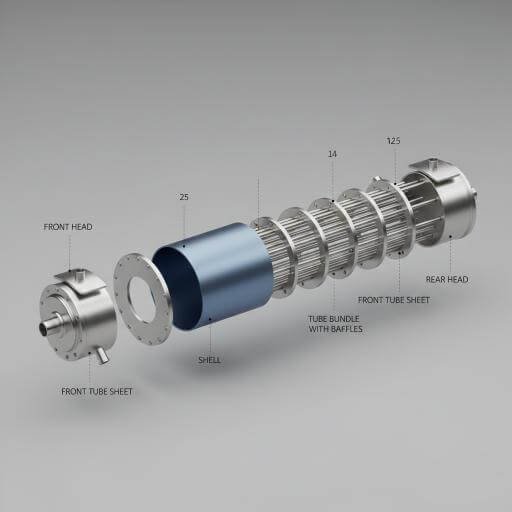

Shell and Tube Heat Exchanger Design Elements

Key mechanical components include:

Tube bundle

Tube sheets

Baffles

Shell

Expansion joints

Baffles improve turbulence and heat transfer but also increase pressure drop, requiring optimization.

Fouling Factors and Design Margin

Fouling reduces heat transfer efficiency over time. Engineers apply fouling factors based on fluid type (cooling water, oil, slurry).

Design margin ensures:

Stable operation between cleanings

Reduced maintenance frequency

Consistent outlet temperatures

Material Selection for Heat Exchangers

Material selection depends on:

Chemical compatibility

Operating temperature

Pressure

Thermal conductivity

Cost

Common materials:

Carbon Steel – economical

SS316L – corrosion-resistant

Duplex SS – high strength

Titanium – chloride resistance

Hastelloy – aggressive chemicals

As an experienced heat exchangers manufacturer in Mumbai, Liuminex carefully select materials like SS316L, Duplex steel, and Hastelloy based on corrosion, temperature, and pressure requirements.

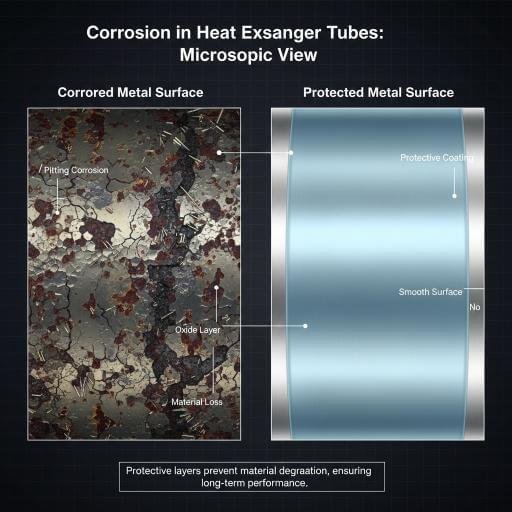

Corrosion and Erosion Considerations

Improper material choice can lead to:

Pitting corrosion

Stress corrosion cracking

Erosion from high velocity

Corrosion allowance is included in design thickness to ensure long service life.

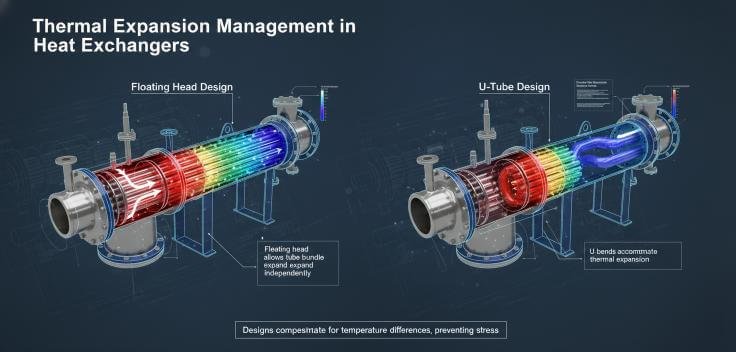

Thermal Expansion and Stress Management

Different materials expand at different rates. Without proper allowances, thermal stress can damage tube sheets or welds.

Solutions include:

Expansion bellows

Floating head designs

U-tube bundles

Design Codes and Standards

Heat exchangers must comply with:

TEMA – mechanical classification

ASME Section VIII – pressure design

API 660 – refinery applications

IS codes – Indian compliance

Compliance ensures safety and global acceptance.

Heat Exchanger Types & Industrial Applications

Heat exchangers are available in multiple designs to suit diverse operating conditions such as pressure, temperature, fouling tendency, viscosity, and space constraints. Selecting the correct type directly impacts efficiency, maintenance cost, and plant reliability.

This section provides a comprehensive breakdown of heat exchanger types, construction details, and real-world industrial applications.

Shell and Tube Heat Exchangers

Shell and tube heat exchangers are the most widely used in chemical processing due to their mechanical robustness and flexibility.

Construction Features:

Cylindrical shell

Tube bundle (straight or U-tube)

Tube sheets

Baffles for turbulence

Floating or fixed head design

Applications:

Reactor heating/cooling

Condensers

Reboilers

High-pressure services

Most chemical plants prefer shell and tube designs supplied by a certified Heat Exchangers Manufacturer due to their robustness and adaptability.

Plate Heat Exchangers

Plate heat exchangers use thin corrugated plates to transfer heat efficiently in compact space.

Key Advantages:

High heat transfer coefficient

Compact footprint

Easy capacity expansion

Low hold-up volume

Limitations:

Lower pressure tolerance

Not suitable for heavy fouling

Applications:

Fine chemicals

Pharma utilities

Food processing

Air Cooled Heat Exchangers (ACHE)

Air cooled heat exchangers use ambient air instead of water, making them ideal for water-scarce regions.

Design Features:

Finned tubes

Axial fans

Plenum chamber

Applications:

Petrochemical plants

Outdoor installations

Remote locations

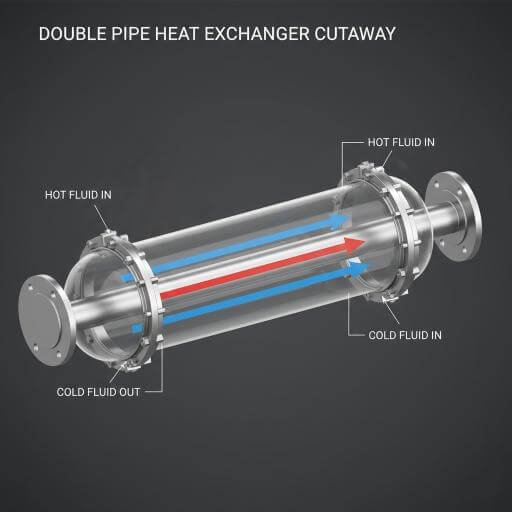

Double Pipe Heat Exchangers

Double pipe exchangers consist of one pipe inside another and are used for small heat duties.

Advantages:

Simple design

Easy maintenance

Suitable for high-pressure fluids

Applications:

Pilot plants

Small process lines

Oil heating

Spiral Heat Exchangers

Spiral heat exchangers feature two flat plates wound into spiral channels.

Advantages:

Self-cleaning effect

Suitable for slurries

Compact design

Applications:

Sludge processing

Waste heat recovery

Viscous fluids

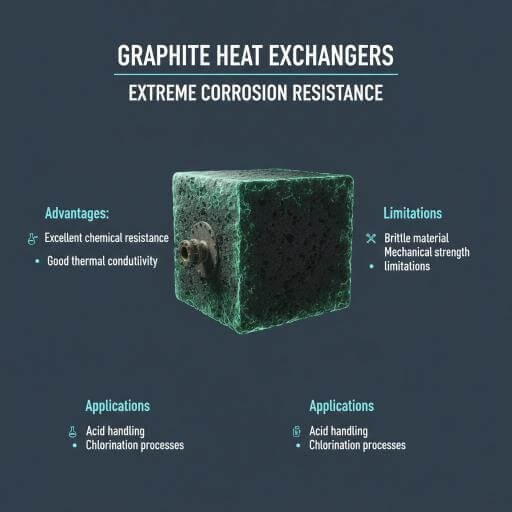

Graphite Heat Exchangers

Graphite exchangers are used where extreme corrosion resistance is required.

Advantages:

Excellent chemical resistance

Good thermal conductivity

Limitations:

Brittle material

Mechanical strength limitations

Applications:

Acid handling

Chlorination processes

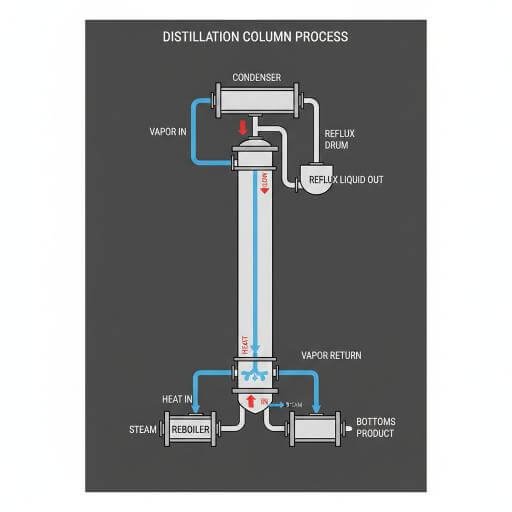

Condensers and Reboilers

These are specialized heat exchangers used in distillation systems.

Condensers:

Convert vapor to liquid

Used in overhead systems

Reboilers:

Provide heat to column bottom

Maintain vapor flow

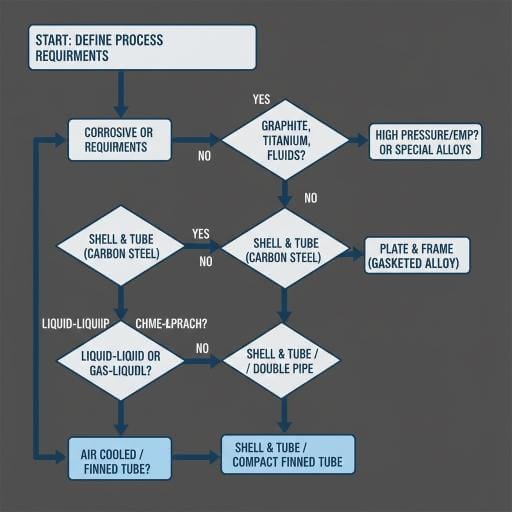

Heat Exchanger Selection Criteria

Selection depends on:

Heat duty

Pressure and temperature

Fouling tendency

Space availability

Maintenance access

Capital and operating cost

Correct selection improves plant reliability and lifecycle cost.

Industrial Applications of Heat Exchangers

Chemical Industry:

Reactor temperature control

Solvent recovery

Pharmaceutical:

Clean utility systems

API processing

Petrochemical:

Crude heating

Gas cooling

Food & Beverage:

Pasteurization

Cooling

A leading Heat Exchangers Manufacturer Liuminex supplies customized solutions for chemical, pharmaceutical, petrochemical, and specialty chemical industries.

Advantages and Limitations of Different Types

| Type | Advantages | Limitations |

|---|---|---|

| Shell & Tube | Robust | Larger footprint |

| Plate | High efficiency | Fouling sensitive |

| Air Cooled | No water | Higher power |

| Double Pipe | Simple | Limited capacity |

| Spiral | Handles slurry | Custom design |

Custom Heat Exchanger Designs

Many chemical processes require custom-engineered exchangers to meet unique conditions such as high viscosity, corrosive fluids, or limited space.

Customization includes:

Special materials

Modified baffle design

Enhanced surface tubes

Safety, Maintenance & Optimization

Importance of Safety in Heat Exchanger Operation

Heat exchangers operate under high pressure and temperature, often handling hazardous chemicals. Any failure can cause leaks, thermal shock, or cross-contamination.

Safety considerations are embedded from design stage to operation, ensuring protection of personnel, environment, and assets.

Common Safety Hazards in Heat Exchangers

Typical risks include:

Tube rupture

Thermal expansion stress

Corrosion-induced leaks

Overpressure conditions

Understanding these hazards enables proactive prevention strategies.

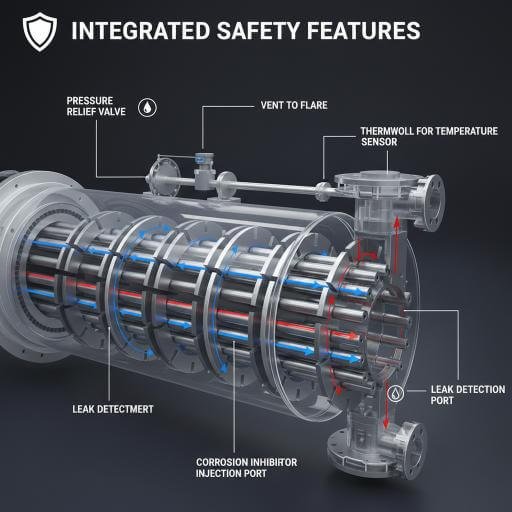

Design Safety Features

Heat exchangers incorporate safety mechanisms such as:

Pressure relief valves

Expansion joints

Corrosion allowance

Leak detection ports

These features prevent catastrophic failures.

Compliance with Safety Standards

Compliance with standards ensures safe operation:

ASME Section VIII

TEMA

API 660

OSHA guidelines

Following these standards reduces operational risk.

Every responsible Heat Exchangers Manufacturer strictly follows ASME, TEMA, and API standards to ensure operational safety and compliance.

Routine Inspection Practices

Regular inspection detects early signs of failure. Common methods:

Visual inspection

Eddy current testing

Ultrasonic thickness measurement

Pressure testing

Inspections improve reliability and lifespan.

Fouling Mechanisms and Impact

Fouling reduces heat transfer efficiency and increases pressure drop. Types include:

Scaling

Biological fouling

Chemical deposition

Particulate fouling

Understanding fouling helps in selecting proper mitigation strategies.

Fouling Prevention Techniques

Preventive methods include:

Chemical treatment

Filtration systems

Velocity control

Surface coatings

Preventing fouling improves performance and reduces downtime.

Cleaning Methods for Heat Exchangers

Cleaning restores performance:

Mechanical cleaning

Chemical cleaning (CIP)

High-pressure water jetting

Selecting the correct method prevents damage.

Performance Monitoring and Optimization

Performance is monitored using:

Temperature approach

Pressure drop trends

Heat duty deviations

Advanced monitoring allows predictive maintenance.

Energy Efficiency Optimization

Optimized heat exchangers reduce:

Steam consumption

Cooling water usage

Power consumption

Energy recovery systems improve overall plant efficiency.

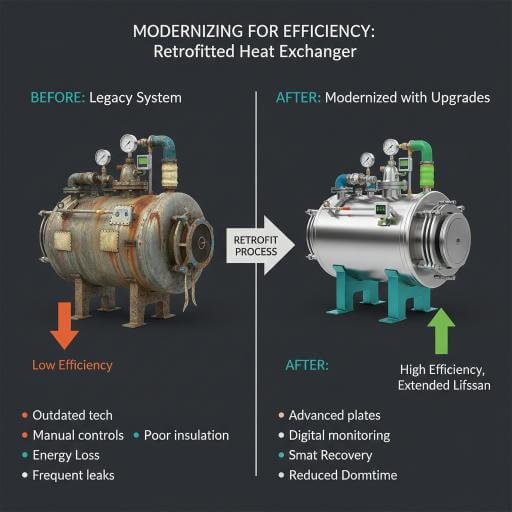

Retrofitting and Upgradation

Older exchangers can be upgraded using:

Enhanced surface tubes

Improved materials

Modern monitoring sensors

Retrofitting improves performance without full replacement.

Emergency Response Planning

Plants must prepare for:

Tube leaks

Sudden pressure spikes

Thermal runaway

Emergency isolation and depressurization systems minimize damage.

Best Practices for Long-Term Reliability

Key practices include:

Scheduled maintenance

Accurate operating parameters

Trained personnel

Documentation and logs

Consistency ensures safe, reliable operation.

Proper maintenance guidelines provided by an experienced Heat Exchangers Manufacturer significantly improve equipment life and plant reliability.

Innovation, Digitalization & Future Outlook

Evolution of Heat Exchanger Technology

Heat exchangers have evolved from simple mechanical devices into intelligent, data-driven systems. Modern designs prioritize energy efficiency, compactness, sustainability, and predictive maintenance.

The increasing complexity of chemical processes demands exchangers that adapt in real time to process variations.

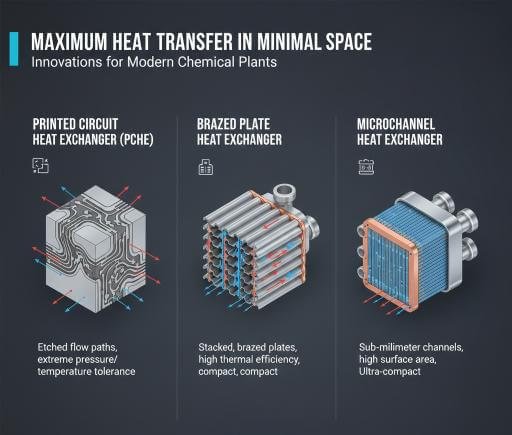

Compact and High-Performance Heat Exchangers

Modern chemical plants require maximum heat transfer in minimal space. Innovations include:

Printed Circuit Heat Exchangers (PCHE)

Brazed Plate Heat Exchangers

Microchannel Heat Exchangers

These designs offer high efficiency and reduced footprint.

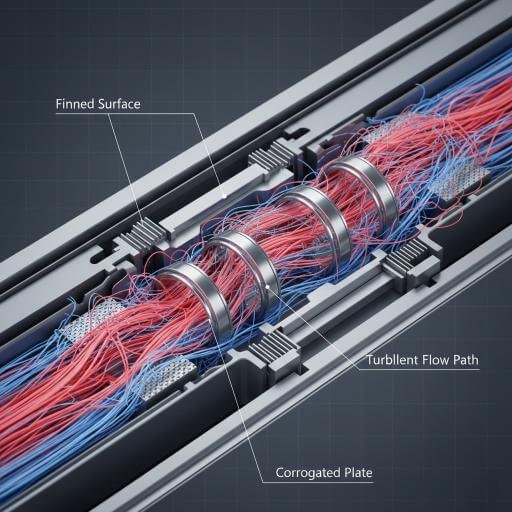

Enhanced Heat Transfer Surfaces

Advanced surface technologies improve thermal performance:

Twisted tubes

Finned tubes

Corrugated plates

Dimpled surfaces

These enhancements increase turbulence without excessive pressure drop.

Advanced Materials and Coatings

New materials enhance durability:

Duplex and super duplex stainless steels

Titanium alloys

Ceramic coatings

Polymer linings

These materials provide superior resistance to corrosion and fouling.

Automation and Smart Heat Exchangers

Smart heat exchangers integrate:

Temperature and pressure sensors

Flow meters

AI-based control systems

PLC and SCADA connectivity

Automation allows self-adjusting performance for optimal efficiency.

A modern Heat Exchangers Manufacturer integrates automation, sensors, and digital monitoring to meet Industry 4.0 requirements.

Digital Twins and Predictive Maintenance

Digital twins simulate real-time exchanger performance:

Predict fouling

Optimize cleaning schedules

Reduce downtime

Predictive maintenance minimizes unexpected failures.

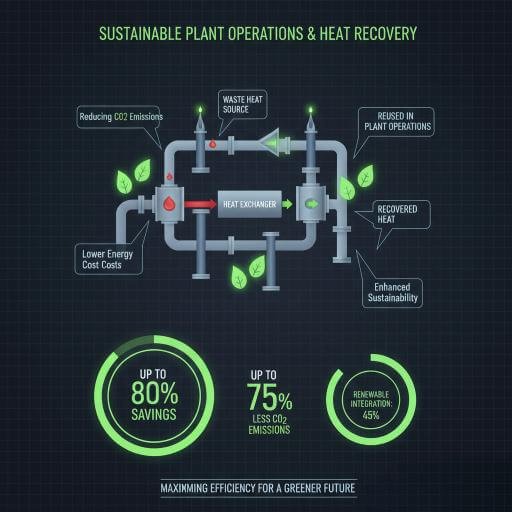

Energy Recovery and Sustainability

Heat exchangers play a key role in:

Waste heat recovery

Carbon emission reduction

Energy integration

Sustainable designs align with global decarbonization goals.

Integration with Industry 4.0

Heat exchangers are becoming part of smart factories:

IoT-enabled monitoring

Cloud-based analytics

Remote diagnostics

Industry 4.0 enhances operational transparency and efficiency.

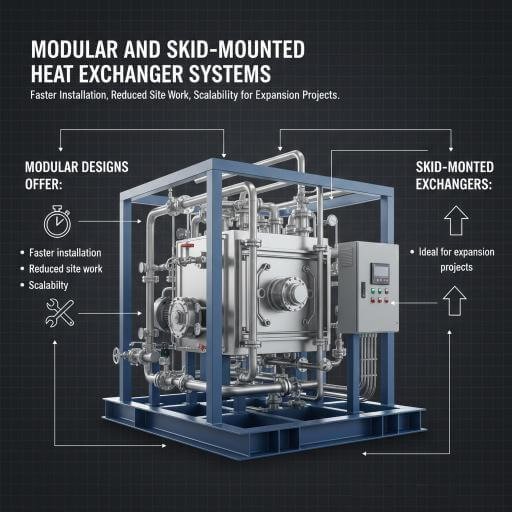

Modular and Skid-Mounted Heat Exchanger Systems

Modular designs offer:

Faster installation

Reduced site work

Scalability

Skid-mounted exchangers are ideal for expansion projects.

Challenges in Advanced Heat Exchanger Implementation

Despite benefits, challenges include:

Higher capital cost

Specialized maintenance

Integration complexity

However, long-term savings outweigh initial investment.

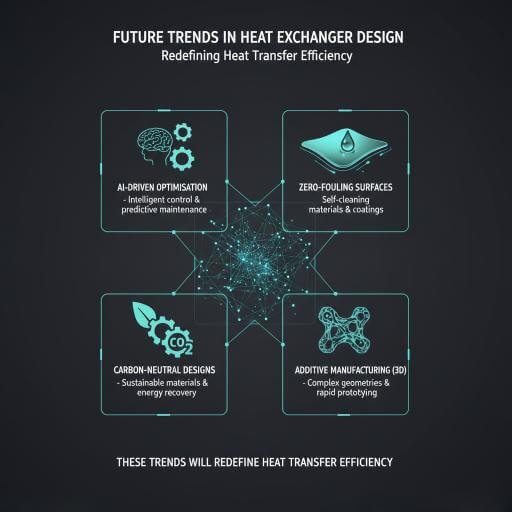

Future Trends in Heat Exchanger Design

Key future trends:

AI-driven optimization

Zero-fouling surfaces

Carbon-neutral designs

Additive manufacturing (3D printing)

These trends will redefine heat transfer efficiency.

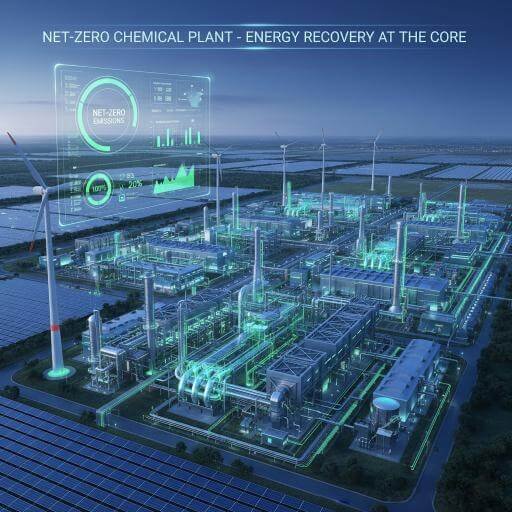

Role of Heat Exchangers in Net-Zero Plants

Heat exchangers enable:

Energy recycling

Process electrification

Reduced fuel usage

They are essential for achieving net-zero targets.

Custom Engineering by Liuminex

As Heat Exchangers Manufacturer in Mumbai Liuminex focuses on:

Application-specific designs

Advanced material selection

Automation-ready systems

Global compliance standards

This ensures long-term value for clients.