Chemical Reactor

What Are Reaction Vessels?

Reaction vessels are specialized containers where chemical reactions occur under controlled conditions of temperature, pressure, and agitation. They form the core of every chemical processing plant, converting raw materials into valuable products through physical and chemical transformations.

Whether in the pharmaceutical, petrochemical, agrochemical, or food processing industry, the efficiency of a reaction vessel determines the yield, purity, and safety of the entire process.

Modern reaction vessels are engineered to maintain precise control over reaction parameters such as heat transfer, mixing intensity, and pressure balance — ensuring predictable reaction kinetics and optimal conversion.

Industries involved in chemical processing prefer working with an experienced Chemical Reactor Manufacturer who understands reaction kinetics, safety requirements, and material compatibility.

Reaction vessels play a critical role in modern process industries, serving as the core equipment where controlled chemical transformations take place. A chemical reactor is specifically designed to manage temperature, pressure, and mixing conditions, ensuring safe and efficient production across sectors. In large-scale manufacturing, industrial reactor vessels are commonly built as a pressure vessel to withstand high operating demands, while systems such as a batch reactor or jacketed reactor allow precise control of heating and cooling cycles.

Within a chemical plant reactor setup, these units often work alongside industrial mixing vessels to maintain uniform reactant distribution and consistent product quality. Specialized applications include pharmaceutical reaction vessels, which must meet strict hygiene and regulatory standards, and petrochemical reaction vessels, engineered to handle high temperatures, corrosive materials, and continuous processing environments.

Importance of Chemical Reactor (Reaction Vessels) in the Chemical Industry

Reaction vessels serve as the heart of chemical synthesis, bridging laboratory research and industrial-scale production. Their importance lies in their ability to handle:

Diverse reaction types – exothermic, endothermic, catalytic, and polymerization reactions.

Extreme operating conditions – high pressures, vacuum operations, or cryogenic temperatures.

Hazardous chemicals – safely containing flammable or corrosive substances.

In chemical plants, the reaction vessel’s performance directly affects throughput, product consistency, and energy efficiency. A well-designed reactor minimizes downtime, ensures safety compliance, and reduces environmental impact through optimized resource use.

Choosing the right Chemical Reactor Manufacturer is essential for achieving consistent product quality and safe reactor operation.

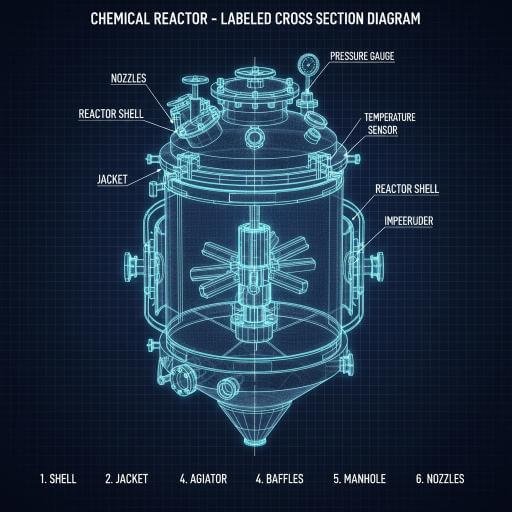

Core Components of a Reaction Vessel

Every reaction vessel comprises several key components that together create a controlled environment for reactions:

Shell (Body): Usually cylindrical and made from materials like SS316L or Hastelloy, the shell forms the main containment.

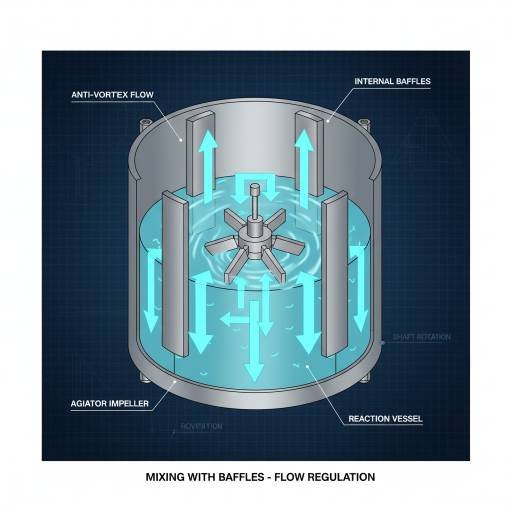

Agitator: Ensures homogenous mixing and heat distribution. Types include propeller, anchor, and turbine agitators.

Baffles: Prevent vortex formation during agitation.

Heating/Cooling Jacket: Controls reaction temperature using steam, hot oil, or chilled water.

Manhole and Nozzles: Allow for feeding reactants, sampling, pressure relief, and instrumentation access.

Pressure/Vacuum Safety Systems: Maintain safe operation limits.

Together, these components provide mechanical strength, process control, and safety — vital for achieving stable reaction performance.

A reputed Chemical Reactor Manufacturer supplies customized reaction vessels for chemical, pharmaceutical, petrochemical, and specialty chemical industries.

Types of Reaction Vessels Based on Operation

Reaction vessels can be categorized based on mode of operation:

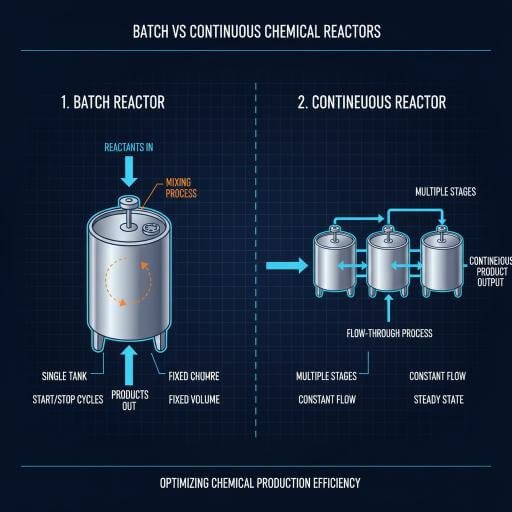

A. Batch Reaction Vessels

These are used when reactions must occur in discrete quantities. Ideal for pharmaceuticals, specialty chemicals, and R&D.

Advantages:

High flexibility for different formulations

Easier cleaning and changeover

Precise control over reaction time and temperature

B. Continuous Reaction Vessels

Used in large-scale, consistent production such as petrochemicals. Reactants flow continuously, and products exit simultaneously.

Advantages:

High throughput

Better heat and mass transfer

Reduced energy per unit product

Types Based on Construction and Function

Reaction vessels are also classified according to mechanical design and purpose:

Jacketed Reaction Vessel: For heating or cooling using a fluid jacket.

Limpet Coil Vessel: Spiral coil wrapped externally for temperature regulation.

Glass-Lined Vessel: For highly corrosive reactions.

Pressure Vessel: Designed for reactions under high pressure.

Vacuum Vessel: For reactions at low pressures or solvent recovery.

Agitated Reactor: Equipped with specialized impellers for mixing.

Selecting the right vessel depends on the chemical nature of reactants, reaction kinetics, and desired product quality.

Different reactor configurations are offered by a specialized Chemical Reactor Manufacturer to suit batch, semi-batch, and continuous chemical processes.

Materials of Construction

Material selection determines durability, corrosion resistance, and compatibility with process fluids. Common materials include:

| Material | Key Properties | Applications |

|---|---|---|

| Stainless Steel (SS316L) | Corrosion-resistant, strong, easy to clean | Pharma, food, fine chemicals |

| Hastelloy C-22/C-276 | Resistant to strong acids and oxidizers | Agrochemicals, specialty chemicals |

| Titanium | Excellent against chloride corrosion | Chlorine-based processes |

| Glass-Lined Steel | Ideal for highly corrosive reactions | Pharmaceuticals, dyes |

| Carbon Steel (CS) | Cost-effective, limited chemical resistance | General chemical processing |

The choice balances process safety, cost, and lifespan. Proper surface finishing (mirror polish or electropolishing) ensures contamination-free operation.

Design Standards and Certifications

Reaction vessels must comply with international design codes to ensure structural integrity and operator safety:

ASME Section VIII Div. 1/2 – Pressure vessel design

IS 2825 – Indian standard for unfired pressure vessels

API 650 / API 660 – Oil and gas industry applications

GMP / cGMP Compliance – For pharmaceutical-grade vessels

PED (Pressure Equipment Directive) – For European export

Certified designs undergo non-destructive testing (NDT) like radiography, ultrasonic testing, and hydrotesting before commissioning.

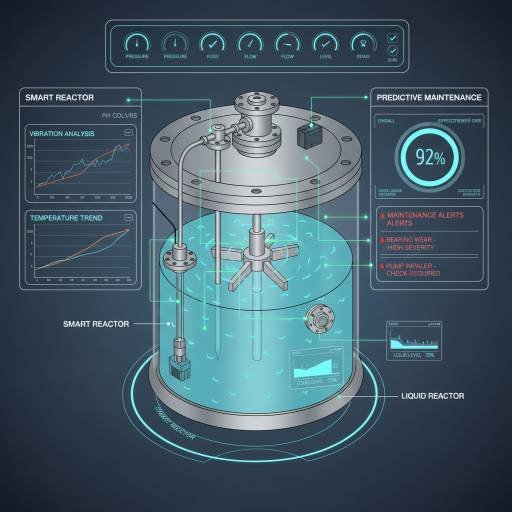

Future Trends in Reaction Vessel Technology

Modern chemical plants are shifting toward smart, automated reaction systems with real-time data acquisition. The next generation of vessels includes:

IoT-enabled sensors for continuous monitoring

Digital twins for virtual process simulation

AI-driven predictive maintenance

Sustainable materials with low carbon footprint

Modular designs for flexible production

These innovations reduce downtime, enhance yield, and make plants more environmentally responsible.

Design and Material Considerations in Reaction Vessels

Why Design Matters in Reaction Vessels

Reaction vessel design is the foundation of safe, efficient, and reliable chemical processing. A well-engineered vessel ensures that temperature, pressure, and mixing parameters are maintained precisely, allowing the desired chemical reaction to proceed with maximum yield and minimum risk.

Designing a reaction vessel is not just about containment—it’s about controlling energy, chemistry, and flow dynamics inside a confined space. Engineers must balance factors like material compatibility, stress limits, heat transfer, and mixing uniformity.

A professional Chemical Reactor Manufacturer follows detailed mechanical and thermal design calculations to ensure reactors perform reliably under extreme operating conditions.

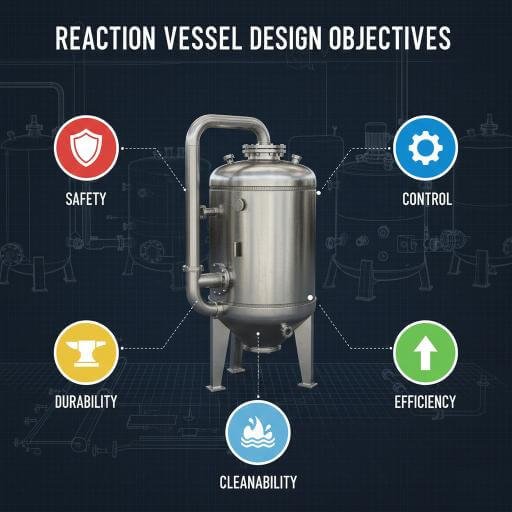

Engineering Objectives in Reaction Vessel Design

The core objectives of reaction vessel design include:

Safety: Withstand high pressure, vacuum, or temperature extremes.

Process Control: Maintain uniform temperature and reactant distribution.

Durability: Resist corrosion, erosion, and fatigue.

Energy Efficiency: Optimize heat exchange and reduce power consumption.

Cleanability: Ensure compliance with GMP for pharma applications.

These objectives guide engineers in selecting the right vessel geometry, material, wall thickness, and support structures.

A modern Chemical Reactor Manufacturer integrates automation, temperature control systems, and digital monitoring to meet Industry 4.0 requirements.

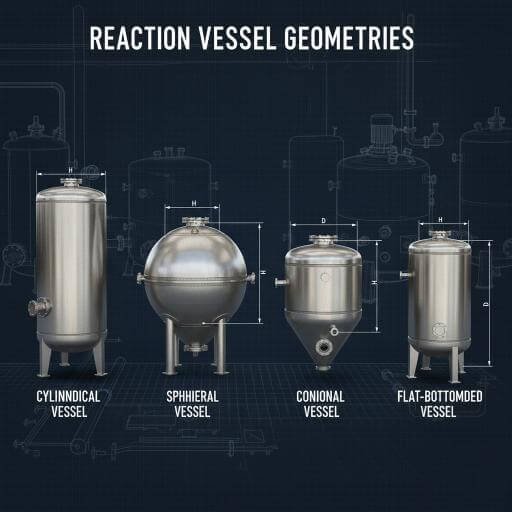

Determining Vessel Geometry and Dimensions

The geometry of a reaction vessel—its diameter, height, and shape—directly affects the process outcomes.

Cylindrical vessels are the most common due to uniform stress distribution.

Spherical vessels offer maximum strength but are costly to fabricate.

Conical bottoms aid in draining and cleaning.

Flat bottoms are used where solids settle easily.

Vessel volume is designed based on batch size, reaction time, and agitator clearance. Engineers also consider head types (torispherical, elliptical, or flat) depending on pressure conditions.

Pressure and Temperature Design Criteria

A reaction vessel must safely handle both internal pressure (from gases or reactions) and external pressure (vacuum conditions).

Design Pressure: Typically set at 1.1 to 1.25 times the maximum operating pressure.

Design Temperature: Must exceed the process temperature to account for excursions.

Allowable Stress: Calculated based on material yield strength, corrosion allowance, and cyclic loading.

Proper stress analysis prevents catastrophic failure under transient loads, ensuring vessel integrity even during abnormal operating conditions.

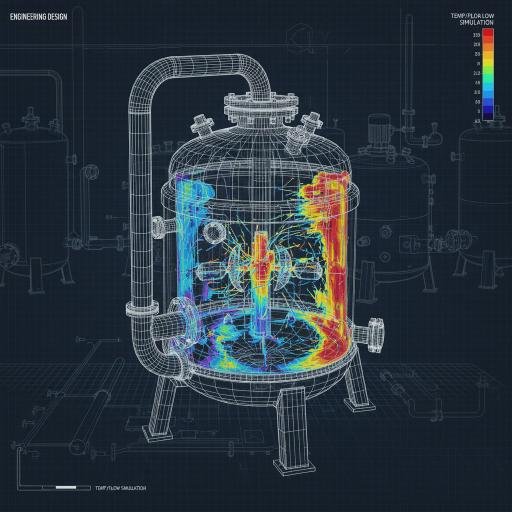

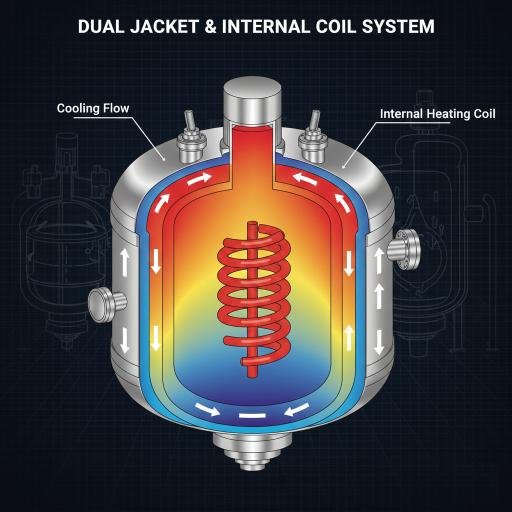

Heat Transfer and Temperature Regulation Systems

Temperature control is crucial because most reactions are temperature-sensitive. Heat is added or removed using jackets or internal coils.

Jacketed vessels: Circulate steam, hot oil, or chilled water through an outer shell.

Limpet coil vessels: Use helical coils welded externally for better heat exchange.

Internal coils: Used for fast heating/cooling in viscous reactions.

Proper design ensures uniform temperature without hot or cold zones that could affect reaction rate or product quality.

An experienced Chemical Reactor Manufacturer selects materials such as SS316L, Duplex steel, or Hastelloy based on corrosion resistance, pressure, and operating temperature.

Heating, Cooling, and Mixing Systems

Why Thermal & Mixing Control Matters

Heating, cooling, and mixing systems form the operational backbone of every reaction vessel. Chemical reactions seldom proceed safely or efficiently without precise control over temperature and homogeneous mixing. Variations in either can lead to undesirable by-products, thermal runaway, poor yield, and even hazardous plant conditions.

Thermal and mixing equipment ensures uniformity, prevents hotspots, accelerates reaction kinetics, and supports optimal energy utilization — making these systems indispensable to reactor engineering.

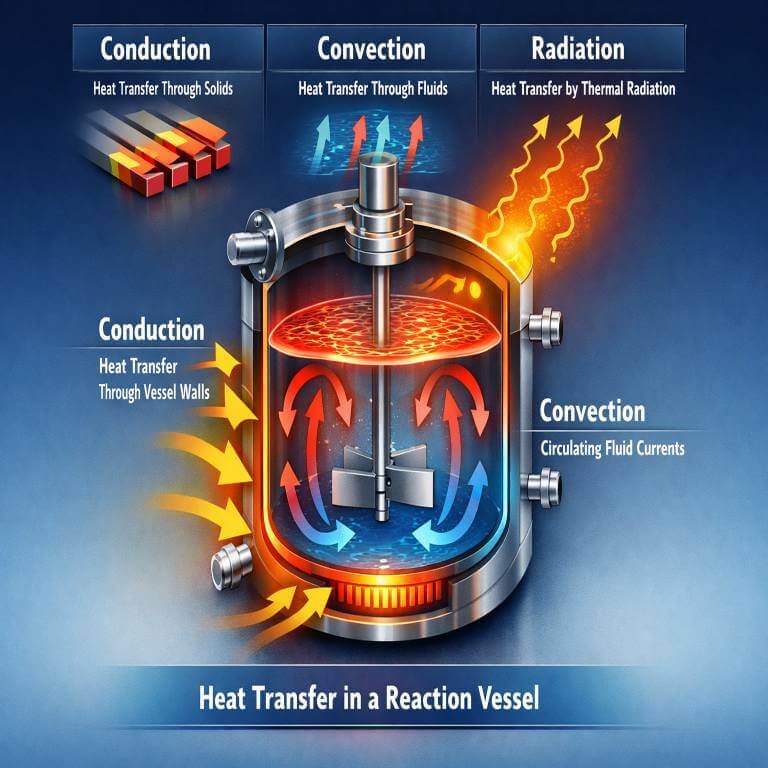

Understanding Heat Transfer in Reaction Vessels

Heat transfer in reaction vessels occurs through conduction, convection, and sometimes radiation, depending on the design and heating medium. Chemical processes may require active heating to initiate reactions or continuous cooling to control exothermic energy release.

Engineers must calculate heat load (Q), heat transfer coefficients (U), and surface area (A) to design an efficient system. These calculations determine whether the system should use jackets, coils, limpet coils, or external heat exchangers.

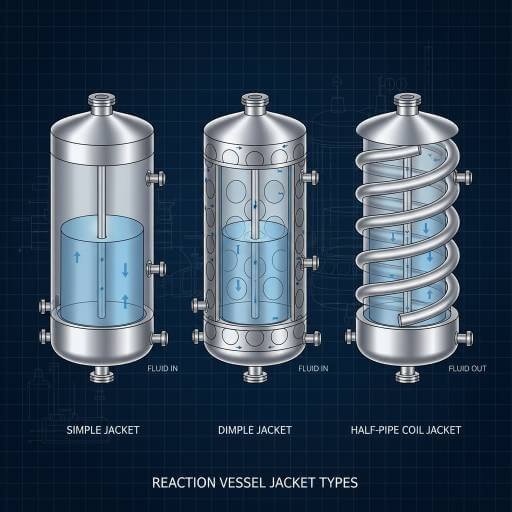

Jacketed Heating and Cooling Systems

The jacketed vessel is the most widely used thermal regulation system. Jackets surround the vessel walls, allowing a heating or cooling medium to flow continuously.

Types of jackets:

Simple Jackets: Single-layer jackets ideal for low-pressure heating systems.

Dimple Jackets: Pressed dimples improve turbulence and heat transfer efficiency.

Half-Pipe Jackets: Spiral welded channels for high-pressure heating media like hot oil.

Jackets ensure uniform temperature distribution along the vessel surface, reducing thermal stress and enhancing process stability.

Limpet Coil Heating Systems

Limpet coils are external helical coils welded around the vessel shell. They are preferred when high-pressure heating or cooling media are required, such as steam or thermal oil.

Advantages of limpet coils:

High-pressure capability

Strong heat transfer performance

Easy to maintain or replace

Suitable for viscous and high-temperature reactions

Limpet coil design is ideal for reactors in chemical, petrochemical, and resin plants.

Internal Coils for Enhanced Heat Transfer

Internal coils are submerged inside the vessel and directly contact the reaction mass. These coils are extremely efficient for high-viscosity fluids, polymerization reactions, or reactions with high thermal loads.

Internal coils may be:

Helical coils

U-shaped coils

Grid coils

While internal coils significantly improve heat transfer rates, they require careful cleaning and maintenance.

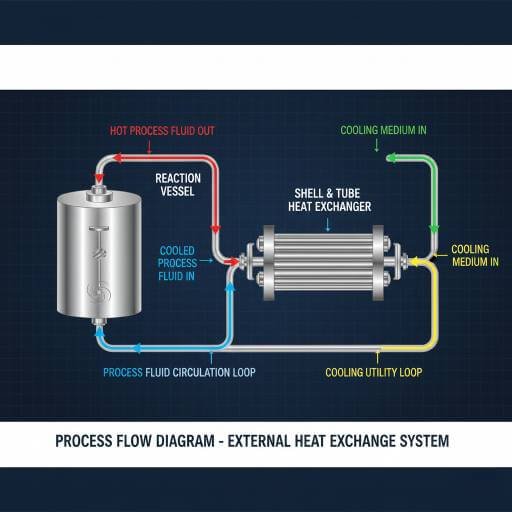

External Heat Exchanger Integration

Some processes require large heat removal capacity beyond what jackets can provide. In such cases, external heat exchangers (shell & tube or plate-type) are connected in a loop with the reactor.

The reaction fluid circulates through the exchanger, where heat is removed or added before returning to the vessel. This system allows fine thermal control, especially for highly exothermic reactions.

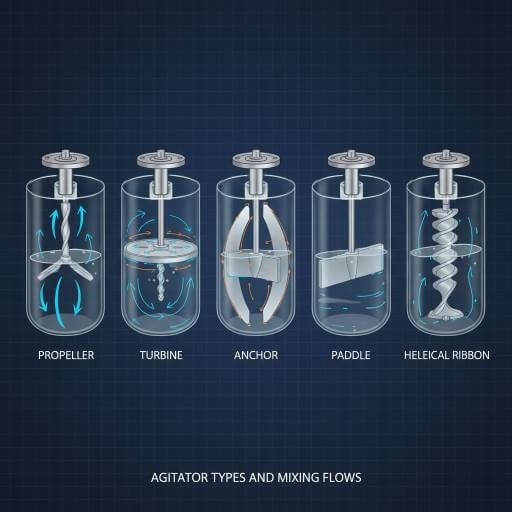

Agitator System Fundamentals

Agitators ensure uniform dispersion of reactants, improved heat transfer, and consistent product quality. Proper mixing avoids temperature stratification, accelerates reaction kinetics, and prevents sedimentation or hotspots.

Agitator performance depends on impeller design, RPM, viscosity, and vessel geometry. Process engineers calculate power number (Np) and Reynolds number (Re) to optimize agitator selection.

Common Agitator Types Used in Reactors

Each impeller type offers unique advantages based on process requirements:

Propeller agitators: High-speed, ideal for low-viscosity liquids.

Turbine agitators: Excellent for gas-liquid reactions and emulsification.

Anchor agitators: Ideal for pastes and thick materials in pharma and adhesives.

Paddle agitators: Medium-speed mixing for general-purpose liquids.

Helical ribbon agitators: Used for ultra-high viscosity applications like polymers.

Proper agitator selection maximizes heat transfer and chemical conversion efficiency.

Baffle Systems for Improved Mixing

Baffles are vertical plates fixed inside the vessel to prevent vortex formation during agitation. Without baffles, the liquid rotates like a vortex without efficient mixing.

Baffles create turbulence zones, enhance solid suspension, improve gas dispersion, and significantly increase mixing uniformity—critical for quality-sensitive reactions.

Heating and Cooling Medium Options

The thermal medium used in jackets or coils depends on the process requirements:

| Medium | Heating/Cooling Capability | Applications |

|---|---|---|

| Steam | High-temperature heating | Pharmaceuticals, dyes |

| Hot Oil (Thermic Fluid) | High-temperature range without pressure | Petrochemicals, polymers |

| Chilled Water | Low-temp cooling | Food, pharma |

| Brine Solution | Deep cooling below 0°C | Specialty chemicals |

| Glycol Water | Controlled cooling | Fine chemicals |

Choosing the wrong medium can lead to thermal shock, corrosion, or reduced heat transfer efficiency.

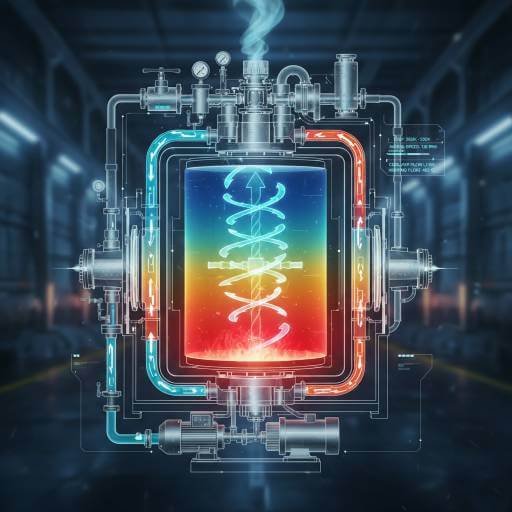

Temperature Control Automation

Advanced systems integrate PID controllers, PLC–SCADA, and IoT temperature sensors to regulate heating and cooling with high precision.

Features include:

Auto-adjusting steam/oil/chilled water flow

Real-time temperature trending

Alarms for high/low temperature

Remote monitoring and predictive maintenance

Automation drastically reduces human error and increases batch consistency.

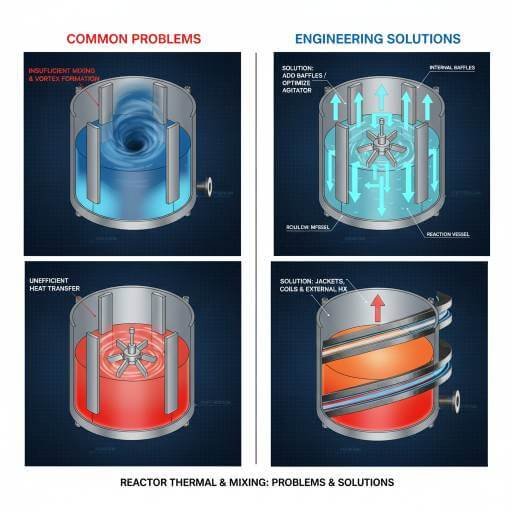

Challenges and Solutions in Thermal & Mixing Design

Common challenges include:

Hot spots in viscous reactions

Poor mixing in tall vessels

Foaming in gas-liquid reactions

Thermal lag in large-volume reactors

Insufficient cooling for exothermic processes

Solutions involve optimizing impeller diameter, adding baffles, using external heat exchangers, or increasing jacket turbulence.

Safety, Instrumentation, and Process Control

Why Safety Is Non-Negotiable in Reaction Vessels

Reaction vessels operate under high pressure, elevated temperature, hazardous chemicals, and continuous agitation, making safety the most critical design and operational consideration. A single failure can result in toxic release, fire, explosion, or catastrophic equipment damage.

Modern chemical plants therefore design reaction vessels with multiple layers of protection, combining mechanical safety devices, advanced instrumentation, and automated control systems. Safety is not treated as a feature—it is built into the core engineering philosophy of the vessel.

Every responsible Chemical Reactor Manufacturer strictly follows ASME, PED, and relevant IS standards to ensure safe reactor design and operation.

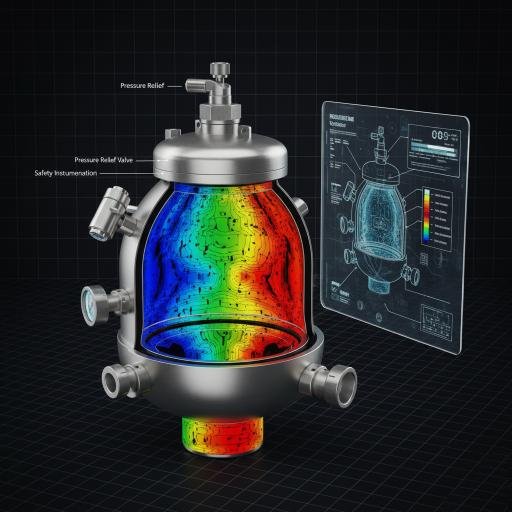

Pressure Management and Overpressure Protection

One of the most dangerous risks in reaction vessels is overpressure, caused by gas generation, runaway reactions, blocked outlets, or thermal expansion.

To manage this, vessels are equipped with:

Pressure Relief Valves (PRVs)

Rupture Discs (Bursting Discs)

Emergency Vent Lines

PRVs automatically release pressure when it exceeds design limits, while rupture discs act as a fail-safe last resort. These devices are sized according to international standards such as ASME Section VIII.

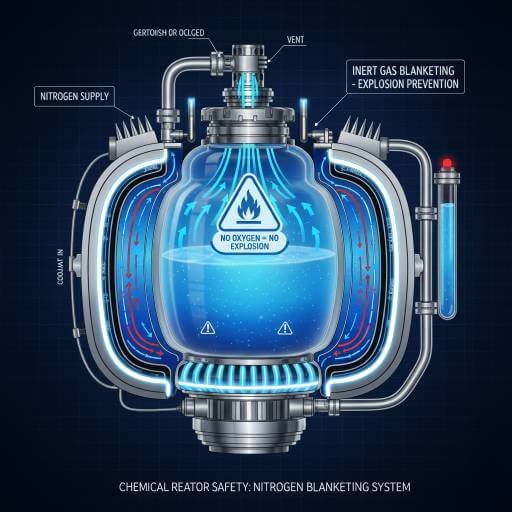

Vacuum Protection Systems

Vacuum conditions are equally hazardous. Sudden cooling, condensation, or improper draining can create negative pressure, leading to vessel collapse.

To prevent this, reaction vessels are fitted with:

Vacuum breakers

Breather valves

Dual pressure-vacuum relief valves

These systems allow controlled air or inert gas entry to maintain structural integrity.

Temperature Safety and Thermal Runaway Prevention

Exothermic reactions can accelerate uncontrollably if heat is not removed quickly. This phenomenon—thermal runaway—is one of the most common causes of reactor accidents.

Safety strategies include:

Redundant temperature sensors

High-temperature alarms

Automatic cooling activation

Emergency quench systems

Interlocked agitator shutdown

Temperature excursions are detected early and corrected automatically through control logic.

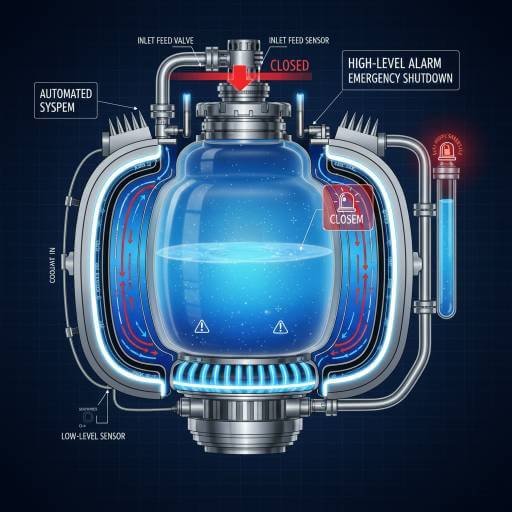

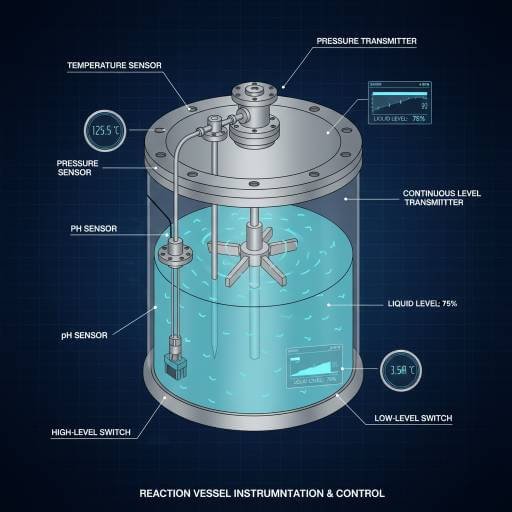

Level Control and Overflow Protection

Incorrect liquid level can result in:

Overflow and chemical spillage

Exposure of heating surfaces

Inefficient mixing

Instrument damage

Reaction vessels therefore use:

Level transmitters (radar, DP, ultrasonic)

High-level and low-level alarms

Automatic feed cutoff systems

These systems ensure stable and predictable reactor operation.

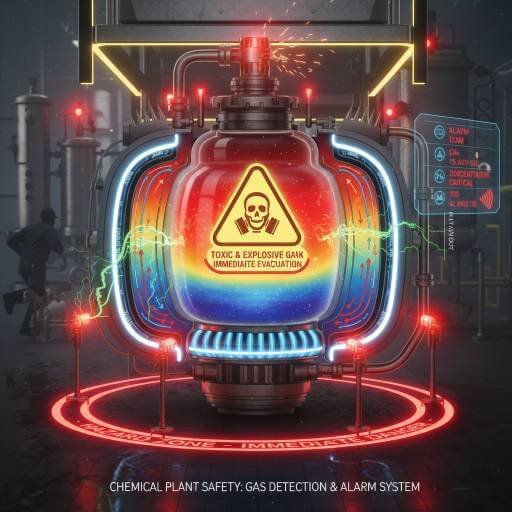

Gas Detection and Hazard Monitoring

In many processes, reaction vessels handle toxic, flammable, or explosive gases. Even small leaks can be life-threatening.

Modern plants integrate:

Hydrogen detectors

VOC gas sensors

Oxygen analyzers

LEL (Lower Explosive Limit) monitoring

These sensors trigger alarms, ventilation, and emergency shutdowns before conditions become dangerous.

Instrumentation in Reaction Vessels

Instrumentation converts physical process variables into measurable signals for monitoring and control. Key instruments include:

Temperature sensors (RTD, thermocouple)

Pressure transmitters

Flow meters

pH and conductivity sensors

Torque sensors on agitators

Accurate instrumentation ensures repeatability, quality control, and regulatory compliance.

Process Control Systems (PLC–SCADA)

Modern reaction vessels operate under PLC-SCADA or DCS systems, enabling automated, real-time control.

Key capabilities include:

Automated batch sequencing

Temperature and pressure PID control

Alarm management

Data logging and batch records

Remote monitoring

Automation reduces human error and ensures consistent batch-to-batch performance.

Interlocks and Emergency Shutdown Systems (ESD)

Interlocks prevent unsafe operations by enforcing logical conditions. For example:

Feed valve opens only if agitator is running

Heating activates only above minimum liquid level

Pressure relief interlocks during abnormal rise

Emergency Shutdown Systems instantly place the reactor in a safe state during critical events.

Inert Gas Blanketing and Explosion Prevention

For flammable reactions, oxygen must be eliminated from the vessel headspace. This is achieved using:

Nitrogen blanketing

Inert gas purging

Oxygen concentration monitoring

This prevents ignition, oxidation, and explosive mixtures.

Compliance with Safety Standards and Regulations

Reaction vessel safety design must comply with:

ASME Section VIII

OSHA Process Safety Management (PSM)

ATEX directives

IEC functional safety standards

GMP safety documentation

Compliance ensures legal operation, insurance approval, and worker safety.

Human–Machine Interface (HMI) and Operator Safety

User-friendly HMI panels allow operators to:

Monitor live reactor conditions

Respond quickly to alarms

Follow SOP-guided workflows

Access safety interlock status

Well-designed HMIs significantly reduce operational risk.

Maintenance, Applications & Future Trends

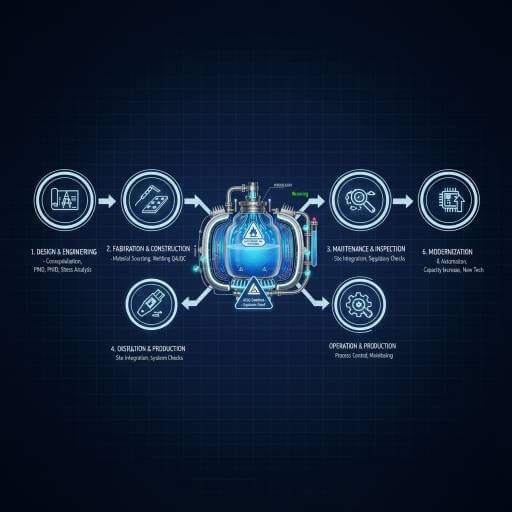

Lifecycle Importance of Reaction Vessels

Reaction vessels are long-term capital assets that operate continuously under harsh chemical and mechanical conditions. Their performance is not defined only by design and fabrication but by how well they are maintained, monitored, and upgraded over time.

Proper lifecycle management ensures:

Long service life

Consistent product quality

Regulatory compliance

Reduced downtime

Improved return on investment (ROI)

This section explores how reaction vessels perform across industries, how they are maintained, and how future innovations will transform reactor technology.

Preventive Maintenance of Reaction Vessels

Preventive maintenance focuses on identifying potential issues before they lead to failures. This approach significantly reduces unplanned shutdowns and safety risks.

Maintenance guidelines provided by an experienced Chemical Reactor Manufacturer help improve reactor life, reduce downtime, and maintain process safety.

Key preventive maintenance activities include:

Visual inspection of shell, nozzles, and welds

Monitoring corrosion and erosion rates

Checking gasket integrity and flange tightness

Verifying agitator alignment and bearing condition

Inspecting safety valves and rupture discs

Maintenance schedules are defined based on operating severity, chemical exposure, and regulatory requirements.

Predictive Maintenance and Condition Monitoring

Advanced plants now rely on predictive maintenance using real-time sensor data. Instead of fixed schedules, maintenance is triggered by actual equipment condition.

Key predictive tools include:

Vibration monitoring on agitators

Temperature trending analysis

Corrosion probes

Motor torque monitoring

AI-based anomaly detection

This approach reduces maintenance cost while preventing catastrophic failures.

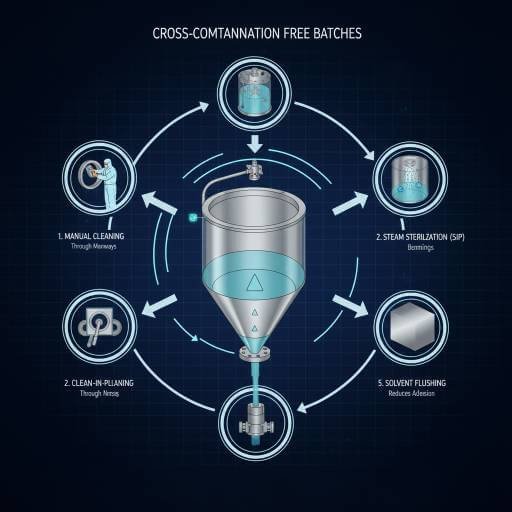

Cleaning, CIP & Contamination Control

For pharmaceutical, food, and specialty chemical industries, cleaning efficiency is critical. Reaction vessels must be free from cross-contamination between batches.

Cleaning methods include:

Manual cleaning through manways

Clean-in-Place (CIP) spray ball systems

Steam sterilization (SIP)

Solvent flushing

Proper surface finishing and drainability enhance cleaning effectiveness and reduce downtime.

Inspection, Testing & Regulatory Audits

Reaction vessels are subject to periodic inspection as per national and international codes.

Typical inspection methods include:

Hydrostatic pressure testing

Radiographic testing (RT)

Ultrasonic testing (UT)

Dye penetrant testing (DPT)

Magnetic particle testing (MPT)

Documentation from these inspections is essential for compliance with ASME, IS, PED, and GMP audits.

Industrial Applications of Reaction Vessels

Reaction vessels are used across a wide spectrum of industries:

Chemical Industry

Acid-base reactions

Polymerization

Resin manufacturing

Specialty chemicals

Pharmaceutical Industry

API synthesis

Crystallization

Fermentation support

Sterile batch processing

Petrochemical Industry

Hydrogenation

Alkylation

Cracking reactions

Food & Beverage

Fermentation

Flavor blending

Thermal processing

Each industry demands specific design, material, and control requirements.

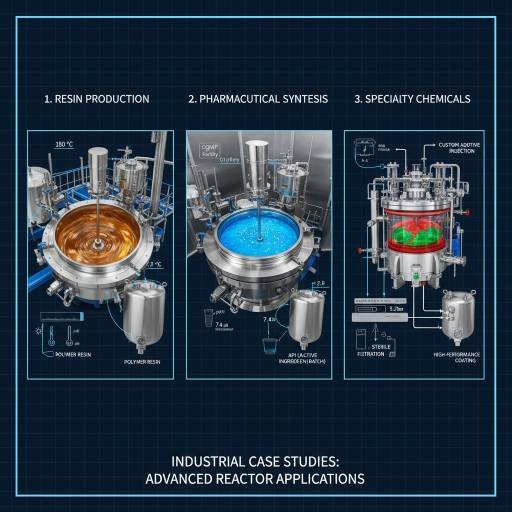

Real-World Use Cases in Manufacturing Plants

Case 1: Resin Manufacturing Plant

High-viscosity polymer reaction using jacketed vessel with anchor agitator and limpet coil heating.

Case 2: Pharmaceutical API Plant

Glass-lined reactor with GMP-compliant polishing and automated batch control.

Case 3: Specialty Chemical Unit

Hastelloy reactor handling corrosive acids under high pressure.

These examples demonstrate how tailored reactor design impacts productivity and safety.

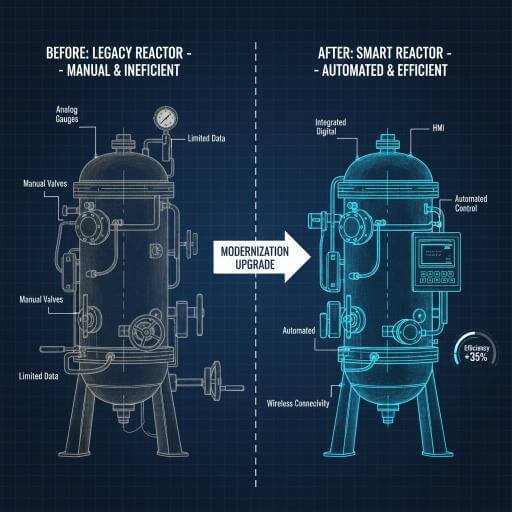

Retrofit, Revamping & Capacity Expansion

Instead of replacing existing vessels, many plants opt for retrofitting to improve performance.

Retrofit options include:

Agitator upgrades

Improved jacket design

Automation integration

Additional safety instrumentation

Capacity expansion through volume optimization

This approach saves capital while extending equipment life.

Common Operational Problems and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Fouling | Poor mixing | Agitator redesign |

| Corrosion | Wrong MOC | Material upgrade |

| Hot spots | Insufficient cooling | External heat exchanger |

| Foaming | Gas entrainment | Anti-foam system |

| Leakage | Gasket failure | Proper torque & materials |

Systematic root cause analysis ensures long-term reliability.

Digitalization & Industry 4.0 in Reaction Vessels

The future of reaction vessels lies in digital transformation.

Emerging technologies include:

Digital twins for process simulation

AI-driven process optimization

Cloud-based performance analytics

Remote monitoring and diagnostics

Autonomous batch execution

These technologies enable smarter, safer, and more efficient chemical plants.

Sustainability and Green Chemistry Integration

Modern reactor systems support sustainable manufacturing by:

Reducing energy consumption

Optimizing solvent usage

Minimizing waste generation

Enabling green chemistry reactions

Supporting heat recovery systems

Sustainability-driven reactor design is becoming a global standard.

Selecting the Right Reaction Vessel Manufacturer

Choosing the right manufacturer determines long-term success. Key evaluation criteria include:

Engineering expertise

Compliance with international codes

Customization capability

Fabrication quality

After-sales support

Manufacturers like Liuminex deliver end-to-end solutions — from design to commissioning.

Reaction Vessels as the Backbone of Chemical Processing

Reaction vessels are not just equipment — they are the core enablers of chemical transformation. From safety and efficiency to sustainability and digitalization, their role continues to expand.With proper design, maintenance, and innovation, reaction vessels deliver consistent performance for decades, making them a strategic investment for chemical manufacturers worldwide.

Partnering with the right Chemical Reactor Manufacturer ensures efficient reaction control, long-term reliability, and compliance with global quality standards.