Heating and Cooling Systems in Chemical Reactor

In the world of chemical processing, reaction vessels (Chemical reactor) are at the heart of production. Whether in pharmaceuticals, agrochemicals, petrochemicals, or specialty chemicals, these vessels facilitate controlled chemical reactions under specific conditions of temperature, pressure, and mixing. Among these variables, temperature control plays the most critical role, as it directly influences:

Reaction kinetics – determining how fast or slow a reaction proceeds.

Product quality – ensuring consistency and purity in the final output.

Safety – preventing dangerous conditions such as runaway reactions, overheating, or pressure build-up.

Energy consumption – reducing operating costs and environmental footprint.

Traditionally, heating and cooling in reactors has been achieved using steam, hot water, or chilled water systems. However, with growing global emphasis on sustainability, energy efficiency, and cost savings, the chemical process industry is shifting toward innovative, energy-efficient heating and cooling systems.

This blog explores in detail how modern energy-efficient heating and cooling solutions enhance the performance of reaction vessels (Chemical reactor), focusing on design considerations, technologies, and future trends.

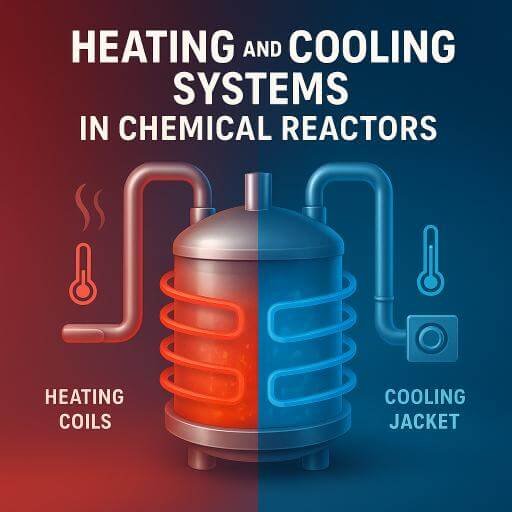

The Role of Heating and Cooling Systems in Chemical reactor

1. Heating in Reaction Vessels (Reactor)

Heating is necessary for:

Initiating reactions that require a minimum activation energy.

Maintaining reaction rates for consistent yield.

Reducing viscosity of certain materials to improve mixing.

Common heating methods include:

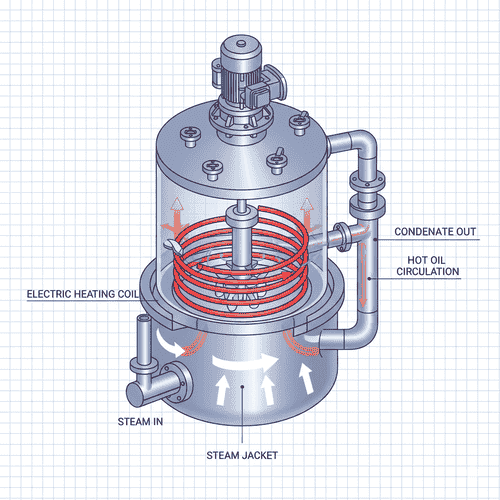

Steam jackets around the vessel.

Electric heating coils or mantles.

Hot oil circulation systems.

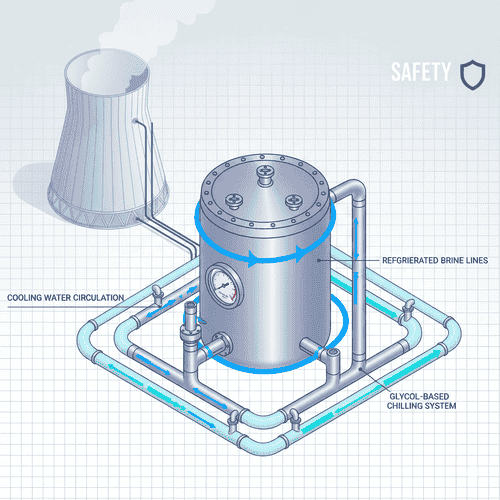

2. Cooling in Reaction Vessels (Reactor)

Cooling is equally critical, particularly in:

Exothermic reactions where heat must be rapidly dissipated.

Post-reaction cooling for downstream processing.

Ensuring thermal safety and avoiding equipment damage.

Common cooling methods include:

Cooling water circulation.

Refrigerated brine systems.

Chilled glycol circulation for low-temperature applications.

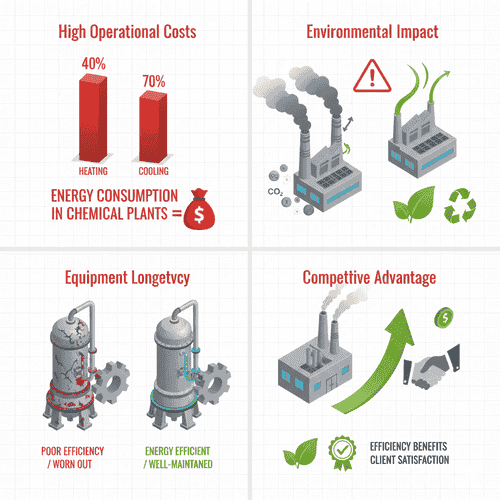

Why Energy Efficiency is a Priority Systems in Chemical reactor

1. High Operational Costs

Heating and cooling consume 40–70% of total energy in a typical chemical processing plant. Improving efficiency directly cuts production costs.

2. Environmental Impact

Inefficient systems contribute to excessive CO₂ emissions. With stricter environmental regulations worldwide, companies must reduce energy waste.

3. Equipment Longevity

Efficient temperature control reduces thermal stress on vessels, jackets, and piping systems, extending equipment life.

4. Competitive Advantage

Energy-efficient operations lower costs, improve product quality, and align with sustainability goals, which are valued by global clients and regulatory agencies.

Design Considerations for Energy-Efficient

Reactor Heating and Cooling

Designing energy-efficient thermal systems requires attention to:

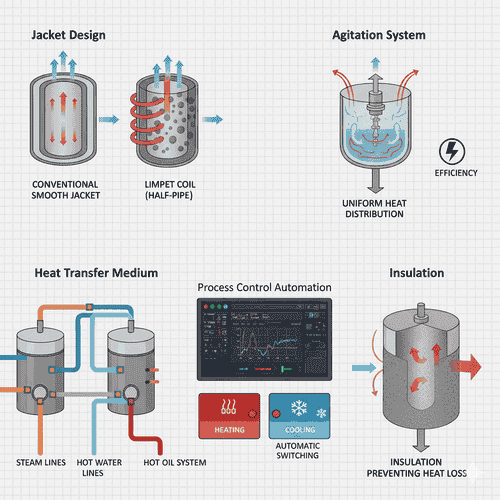

Jacket Design

Conventional jackets (single shell with steam/hot water circulation).

Limpet coils (external half-pipe coils for improved heat transfer).

Dimple jackets (lightweight, high-pressure resistant, energy-saving).

Agitation System

Proper mixing ensures uniform heat distribution, reducing localized overheating or cooling inefficiency.

Energy-efficient impeller designs can reduce power consumption by up to 20%.

Heat Transfer Medium

Choosing between steam, hot water, thermal oil, or refrigerants affects both energy efficiency and safety.

Example: Hot oil systems minimize scaling and corrosion, extending lifespan.

Insulation

High-performance insulation reduces heat loss, especially in continuous operations.

Process Control Automation

PLC/SCADA-based controls optimize real-time energy usage, switching between heating and cooling to maintain ideal setpoints without overshooting.

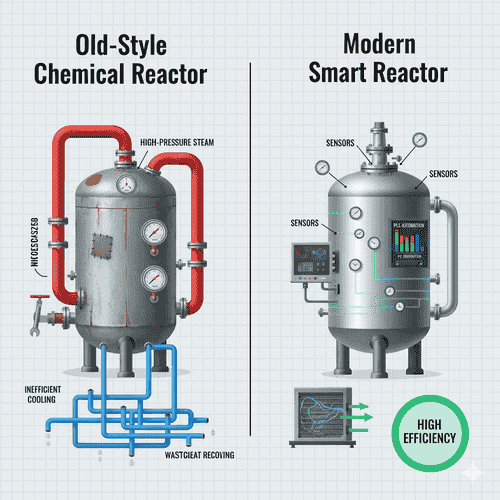

Traditional vs Energy-Efficient Systems in Chemical reactor

| Aspect | Traditional Systems | Energy-Efficient Systems |

|---|---|---|

| Heat Source | High-pressure steam | Optimized low-pressure steam, hot water, thermal oil |

| Cooling Medium | Once-through water | Closed-loop chilled systems with recovery |

| Energy Recovery | Rare | Integrated waste-heat recovery |

| Control | Manual or semi-automated | Fully automated PLC/SCADA with sensors |

| Efficiency | 40–50% | 70–90% |

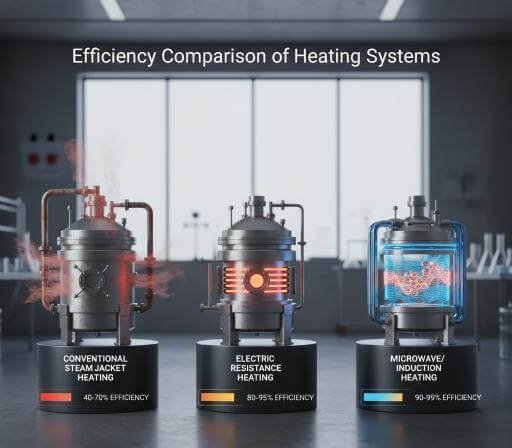

Types of Heating Systems in Reaction Vessels and Their Efficiency

Heating is one of the most energy-intensive operations in a chemical reactor. The choice of heating system affects not only the reaction kinetics and safety but also the energy footprint of the entire plant. In this section, we’ll analyze different heating systems used in reaction vessels, their efficiency levels, and modern innovations that make them more sustainable.

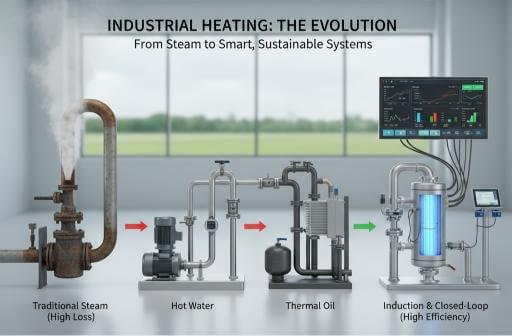

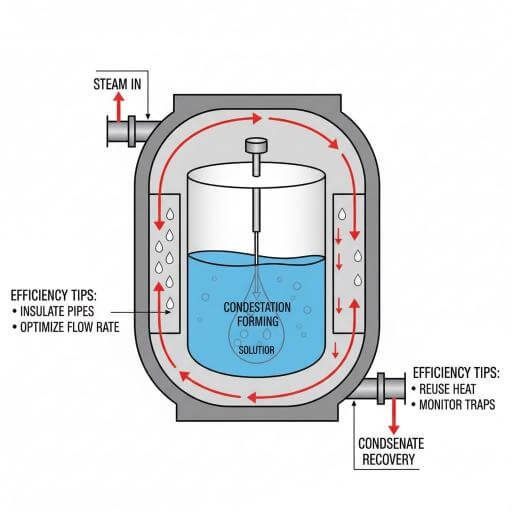

1. Steam Heating Systems in Chemical reactor

Steam has been the traditional heating medium in chemical plants due to its availability and cost-effectiveness. Steam jackets and coils circulate hot steam around the vessel, transferring heat by condensation on the vessel walls.

Advantages:

Rapid and uniform heating.

Easy to control with pressure regulation.

Widely available in industrial setups.

Disadvantages:

High energy losses through condensation.

Requires boiler operations, which add cost and emissions.

Scaling and corrosion reduce heat transfer efficiency.

Efficiency Tips:

Switching from high-pressure to low-pressure steam can save up to 20% energy.

Using steam traps and condensate recovery systems reduces wastage.

2. Hot Water Heating Systems in Chemical reactor

Hot water is increasingly being adopted as a safer, more energy-efficient alternative to steam. By circulating pressurized hot water in the reactor jacket, industries achieve steady and controlled heating.

Advantages:

More stable temperature control compared to steam.

Lower risk of scaling and corrosion.

Energy savings through recirculation.

Disadvantages:

Limited to medium temperature processes (up to ~200 °C).

Requires insulated piping and pumps.

Efficiency Tips:

Use variable frequency drive (VFD) pumps to optimize water circulation.

Integrate with waste-heat recovery systems from boilers or condensers.

3. Thermal Oil Heating Systems in Chemical reactor

For high-temperature applications, thermal oil is a superior heating medium. It eliminates problems of scaling and corrosion, while providing consistent heat up to 350 °C or more.

Advantages:

Wide operating range without pressurization.

Higher efficiency at elevated temperatures.

No steam-related safety hazards.

Disadvantages:

Higher initial investment.

Requires monitoring for oil degradation.

Efficiency Tips:

Use closed-loop circulation systems to minimize energy loss.

Regularly monitor oil condition to prevent efficiency drop.

4. Electric Heating Systems in Chemical reactor

Electric heaters (mantles, immersion heaters, or heating cartridges) are used in smaller or specialized reactors. With growing renewable energy integration, electric heating is emerging as a cleaner alternative in certain cases.

Advantages:

Precise temperature control.

Compact design, no external boiler required.

Easy to automate with sensors.

Disadvantages:

Higher operating costs where electricity is expensive.

Not always feasible for large-scale production.

Efficiency Tips:

Combine with smart controllers to prevent overheating.

Use renewable electricity sources to reduce carbon footprint.

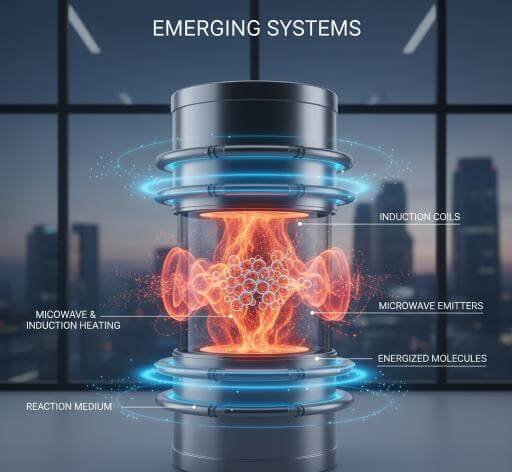

5. Microwave and Induction Heating (Emerging Systems)

Modern research is exploring microwave and induction heating for reaction vessels, especially in pharmaceuticals and specialty chemicals. These methods deliver energy directly to the molecules or vessel wall, minimizing losses.

Advantages:

Extremely fast heating rates.

High selectivity and efficiency.

Compact equipment size.

Disadvantages:

High capital cost.

Limited industrial adoption (currently more in labs and pilot plants).

Efficiency Tips:

Best used in batch processes requiring rapid heating cycles.

Combine with IoT sensors for precise monitoring.

Efficiency Comparison of Heating Systems in Chemical reactor

| Heating System | Max Temperature (°C) | Efficiency Range | Applications |

|---|---|---|---|

| Steam | ~200 | 40–60% | General chemical processing |

| Hot Water | ~200 | 60–75% | Pharma, food, medium-temp reactions |

| Thermal Oil | ~350+ | 70–85% | High-temp chemical & petrochemical processes |

| Electric Heating | ~250 | 70–90% | Small-scale, specialty reactors |

| Microwave/Induction | ~250+ | 80–95% | Emerging, pharma, specialty fine chemicals |

Types of Cooling Systems in Reaction Vessels and Their Efficiency

While heating drives chemical reactions, cooling is just as critical to maintain safe, efficient, and controlled operations in reaction vessels. Many exothermic reactions release large amounts of heat, which—if not removed quickly—can lead to runaway reactions, equipment failure, or even explosions.

This section explores the major cooling systems used in chemical reactors, their advantages and disadvantages, and how industries can improve their energy efficiency while maintaining safety and productivity.

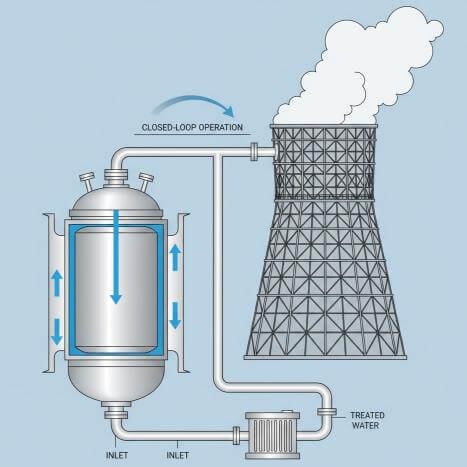

1. Cooling Water Circulation Systems

Cooling water is the most widely used method in chemical reactors due to its availability and low cost. Water flows through the jacket or coils surrounding the vessel, absorbing heat from the reaction mass.

Advantages:

Simple and inexpensive setup.

Rapid cooling for moderate heat loads.

Easy to integrate with cooling towers.

Disadvantages:

Water wastage if operated as once-through system.

Scaling and fouling reduce heat transfer efficiency.

Not suitable for very low-temperature requirements.

Efficiency Tips:

Switch from once-through to closed-loop water systems.

Use treated water to prevent scaling.

Optimize flow rates with automated valves.

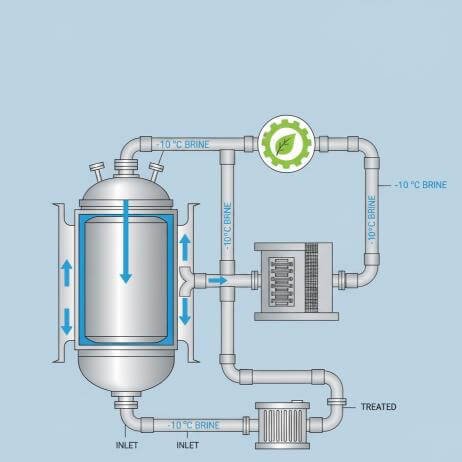

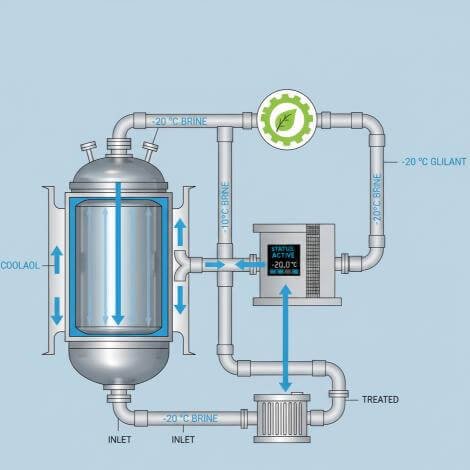

2. Brine-Based Refrigeration Systems in Chemical reactor

For lower temperature requirements (e.g., -5 °C to -20 °C), brine solutions (such as calcium chloride brine) are used. Brine is circulated through jackets or coils connected to refrigeration compressors.

Advantages:

Can achieve sub-zero cooling.

Stable cooling for continuous operations.

Widely used in pharma and specialty chemicals.

Disadvantages:

Brine leakage can cause corrosion.

Higher energy consumption compared to water.

Requires regular monitoring of brine concentration.

Efficiency Tips:

Use insulated piping to reduce thermal losses.

Employ variable load compressors to match cooling demand.

3. Chilled Glycol Systems in Chemical reactor

Glycol-based chillers are commonly used in processes requiring consistent cooling at low to ultra-low temperatures (down to -40 °C). Glycol offers greater flexibility and stability compared to brine.

Advantages:

Wide temperature range.

Less corrosive than brine.

Compatible with advanced refrigeration units.

Disadvantages:

Higher operational cost than water systems.

Requires monitoring of glycol concentration to maintain efficiency.

Efficiency Tips:

Combine with heat recovery chillers.

Use multi-stage chillers to reduce energy consumption.

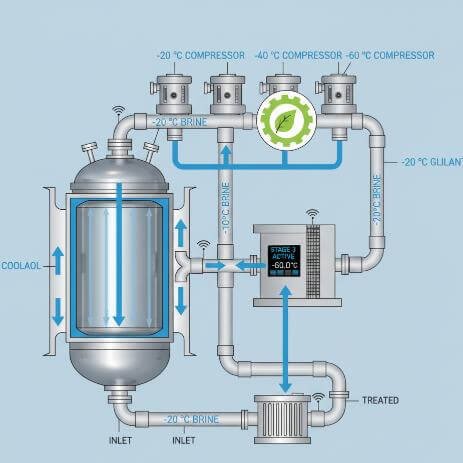

4. Cascade Refrigeration Systems in Chemical reactor

In highly specialized applications (e.g., pharmaceuticals, cryogenics, or specialty polymers), cascade refrigeration systems are used for ultra-low temperature operations, sometimes below -60 °C.

Advantages:

Can reach extremely low temperatures.

Allows precise control for sensitive reactions.

Useful for pilot plants and R&D labs.

Disadvantages:

Very high capital and operating cost.

Complex system with multiple compressors.

Requires expert maintenance.

Efficiency Tips:

Best for specialized small-batch applications rather than large-scale processes.

Integrate with IoT sensors for predictive maintenance.

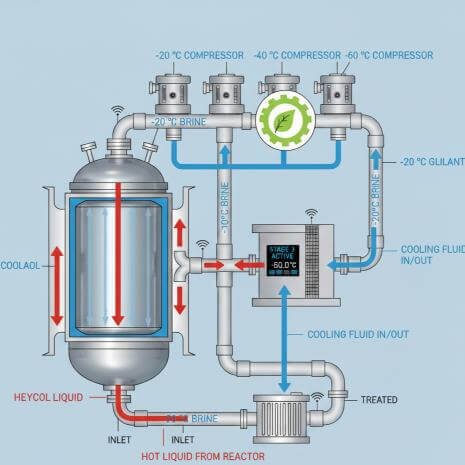

5. Heat Exchanger-Assisted Cooling

Instead of cooling directly in the jacket, some systems employ external heat exchangers. The reactor fluid is circulated through a heat exchanger where it transfers heat to a cooling medium.

Advantages:

Reduces load on reactor jacket.

Provides high flexibility in cooling design.

Can use multiple cooling media in a single setup.

Disadvantages:

Increases piping and pumping requirements.

Slight delay in response time compared to direct cooling.

Efficiency Tips:

Use plate heat exchangers for high efficiency.

Optimize circulation with variable frequency drives (VFDs).

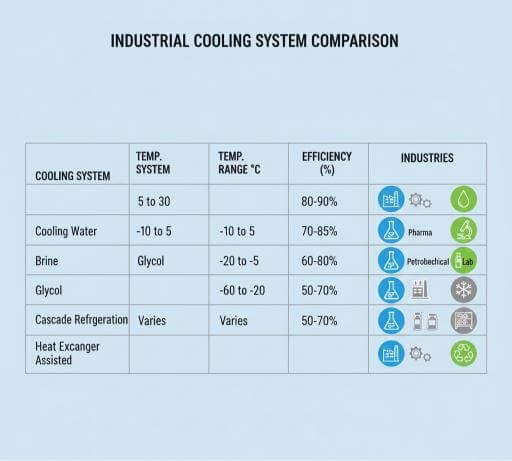

Efficiency Comparison of Cooling Systems in Chemical reactor

| Cooling System | Temperature Range (°C) | Efficiency Range | Applications |

|---|---|---|---|

| Cooling Water | ~20–30 | 40–60% | General cooling, moderate exothermic reactions |

| Brine Cooling | -5 to -20 | 50–70% | Pharma, specialty chemicals |

| Chilled Glycol | -20 to -40 | 60–80% | Low-temperature pharma & polymers |

| Cascade Refrigeration | -40 to -60+ | 70–85% | Cryogenics, R&D, sensitive materials |

| Heat Exchanger-Assisted | Flexible | 65–90% | High-efficiency process plants |

Automation, Control, and Smart Energy Management in Reactor Heating & Cooling Systems

Chemical processing plants no longer rely solely on manual adjustments for temperature control. With Industry 4.0 and digital transformation, reactors are equipped with automation, sensors, and smart energy management systems that significantly reduce waste and optimize performance.

This section explains how automation and control technologies are reshaping reactor heating and cooling systems for efficiency, safety, and sustainability.

1. Process Control Automation

Automation enables precise temperature control in reactors by continuously monitoring conditions and adjusting heating or cooling inputs.

Key Features:

PID Controllers (Proportional–Integral–Derivative) regulate heating/cooling with minimal overshoot.

SCADA & PLC Systems provide centralized monitoring.

Automated Valves & Pumps ensure optimal flow rates.

Benefits:

Reduces operator error.

Minimizes energy overshoot (no unnecessary heating/cooling).

Maintains consistent product quality.

2. IoT Sensors and Real-Time Monitoring

Internet of Things (IoT) sensors allow continuous data collection on temperature, pressure, flow rates, and energy usage. This data is transmitted in real-time for monitoring and optimization.

Applications:

Early detection of abnormal temperature spikes.

Tracking energy consumption trends.

Remote monitoring across multiple plants.

Benefits:

Reduces unplanned downtime.

Provides actionable insights for efficiency improvement.

Enables predictive maintenance.

SEO Keywords: IoT-enabled reactors, real-time monitoring in chemical plants, smart sensors for heating and cooling.

3. Predictive Maintenance with AI and Machine Learning

Instead of waiting for failures, AI-driven predictive maintenance analyzes sensor data to predict when equipment needs service.

Examples:

Detecting scaling inside jackets before efficiency drops.

Predicting pump wear in circulation systems.

Identifying abnormal heat exchanger fouling patterns.

Benefits:

Extends equipment life.

Saves costs by preventing breakdowns.

Improves overall energy efficiency.

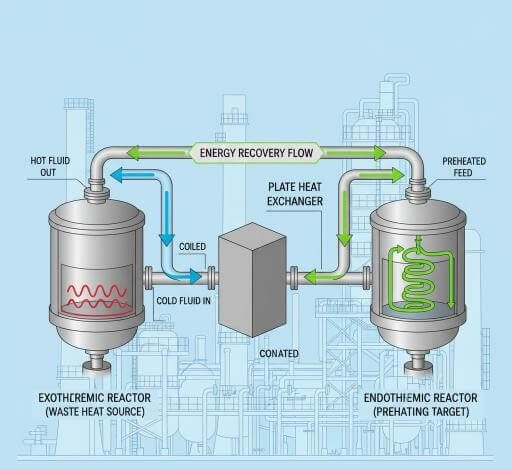

4. Energy Recovery and Heat Integration

A major step toward efficiency is recovering waste heat from reactor systems and reusing it elsewhere in the plant.

Methods:

Condensate Recovery Systems – reuse hot condensate from steam jackets.

Heat Exchangers – transfer excess heat to preheat feedstock.

Integrated Heating & Cooling Loops – use waste heat from one process to drive another.

Benefits:

Cuts fuel and electricity consumption.

Reduces greenhouse gas emissions.

Improves plant sustainability credentials.

5. Smart Energy Management Systems (SEMS)

SEMS are advanced platforms that combine automation, IoT, and analytics to optimize energy usage across the entire plant.

Core Features:

Real-time energy dashboards.

Automatic load balancing between heating and cooling units.

AI-based optimization to cut energy peaks.

Benefits:

Achieves 15–25% reduction in energy consumption.

Ensures compliance with ISO 50001 (energy management standard).

Enhances competitiveness by reducing operating costs.

6. Case Study Snapshot – Pharma Plant Efficiency Upgrade

A pharmaceutical company upgraded its jacketed reactors by integrating IoT sensors, predictive maintenance, and SEMS.

Results:

20% reduction in steam consumption.

25% increase in cooling efficiency through optimized chiller use.

ROI achieved in 18 months due to lower energy bills.

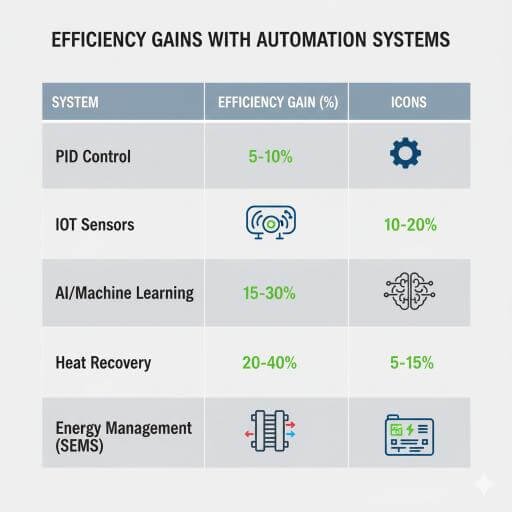

Efficiency Gains with Automation and Smart Control

| Feature | Efficiency Gain | Additional Benefits |

|---|---|---|

| PID Controllers | 5–10% | Reduced overshoot |

| IoT Sensors | 10–15% | Predictive monitoring |

| AI Predictive Maintenance | 15–20% | Less downtime |

| Heat Recovery Systems | 15–25% | Reduced fuel usage |

| Smart Energy Management (SEMS) | 20–30% | ISO compliance, cost savings |

Smart Technologies, AI Control, and Sustainable Heating Solutions

The journey toward energy efficiency in chemical reactor design is evolving faster than ever. With rising energy costs and the global push for sustainability, the next generation of chemical reactors is not just about precise temperature control — it’s about intelligent, connected, and eco-friendly performance. In this final part of our series on Energy-Efficient Heating and Cooling Systems in Reaction Vessels, we explore how smart technologies, AI-based thermal optimization, and renewable energy integration are redefining industrial reactor operations. From IoT-enabled monitoring and predictive analytics to waste heat recovery and hybrid heating systems, the future of process efficiency lies in combining innovation with environmental responsibility.

At Liuminex Projects and Equipments Pvt. Ltd., we are pioneering this transformation by designing AI-ready, energy-smart reactors tailored for chemical, pharmaceutical, and agrochemical industries. This part unveils how tomorrow’s reactors will be smarter, greener, and more efficient — setting a new benchmark for sustainable chemical processing.

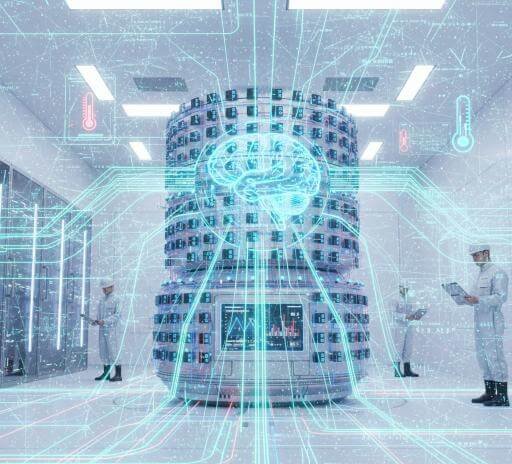

1. Smart and Connected Reactors

Modern industrial reactors are evolving beyond traditional mechanical systems — they’re becoming intelligent, connected, and self-optimizing.

Smart technologies such as IoT sensors, machine learning, and predictive analytics are transforming the way heating and cooling systems operate.

How It Works

IoT sensors continuously monitor temperature, pressure, flow rate, and energy consumption.

The data is fed into an analytics platform, allowing the system to automatically adjust heating and cooling rates for maximum efficiency.

This not only saves energy but also prevents overheating, thermal shocks, and unnecessary cycling.

Benefits

Real-time performance tracking

Automated fault detection and alerts

Reduced manual intervention

Predictive maintenance for heat exchangers and jackets

Example:

A pharmaceutical company integrated IoT-based thermal sensors into its reactor jacket system. The smart system automatically balanced heat load between multiple vessels, reducing total energy use by 15% in one year.

2. Integration of AI for Thermal Optimization

AI is not just monitoring — it’s learning.

Artificial intelligence can analyze years of process data to identify optimal heating and cooling cycles for specific reactions.

For instance, AI can detect that a certain polymerization process performs better if heating ramps slower during the first 20 minutes and cooling is delayed slightly at the end. This kind of fine-tuning is beyond what humans can consistently achieve.

Key Advantages

Enhanced reaction yield through precision control

Energy use optimization by eliminating overshoot

Continuous learning for future batch improvements

Automatic detection of thermal inefficiencies

Industry Trend:

Many modern chemical reactor manufacturers (like Liuminex) are designing AI-ready control systems, allowing plant operators to easily integrate smart modules in the future without replacing core equipment.

3. Renewable Energy Integration

Energy-efficient heating and cooling is no longer limited to internal design — it’s about how energy is sourced.

The next generation of chemical plants will integrate renewable energy directly into reactor operations.

Examples of Integration

Solar thermal systems: Solar concentrators provide hot oil or steam for reactor heating.

Geothermal cooling: Underground loops maintain stable cooling water temperatures.

Biogas-fired heaters: Replaces natural gas for steam generation.

Renewable-powered chillers: Run by solar photovoltaic energy.

This not only reduces emissions but also shields plants from volatile fossil fuel costs.

Real-World Example:

A fine chemicals company in Gujarat installed a solar-assisted thermal oil heater for its jacketed reactors, cutting fossil fuel use by 30% annually.

4. Waste Heat Recovery and Reuse

Every degree of waste heat that escapes a plant is lost potential energy.

Advanced facilities are increasingly using waste heat recovery systems (WHRS) to reclaim this energy from reactor jackets, condensers, and distillation columns.

Common Recovery Methods

Heat exchangers to transfer jacket outlet heat to feed preheating.

Thermal oil loops that reuse residual heat for other batches.

Vapor recompression systems for condensation and reuse.

Integrated heat recovery networks across multiple units.

This leads to 10–25% lower energy consumption overall — without affecting product quality.

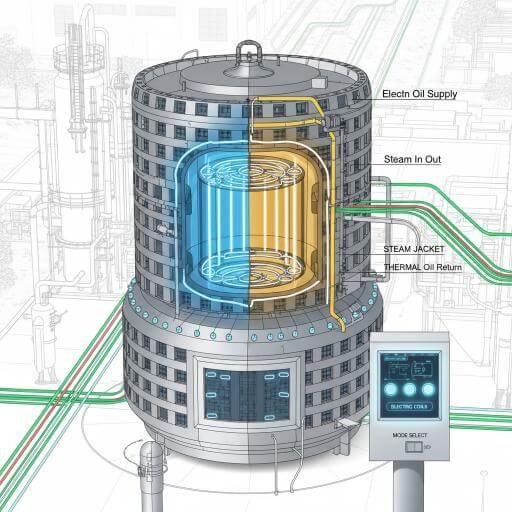

5. Hybrid Heating Systems in Chemical reactor

A growing innovation in chemical processing is hybrid heating systems — combining electric, steam, and thermal oil systems in one setup.

Operators can switch between modes based on process phase or energy cost.

For instance:

Start with electric heating for quick ramp-up.

Switch to steam heating for steady-state operation.

Use thermal oil for slow cooling or heat retention.

Advantages

Flexible operation across different reactions

Reduces peak energy demand

Optimized power usage from multiple sources

Greater reliability during maintenance

6. Case Studies: Energy Efficiency in Action

Case 1: Petrochemical Plant – Hybrid Heating Optimization

A petrochemical plant in Maharashtra upgraded to a hybrid heating system combining steam and electric elements.

By switching automatically based on temperature profiles, the system achieved 22% energy savings and improved temperature stability.

Case 2: Pharmaceutical Reactor – Smart Cooling Integration

A pharma company integrated IoT-based cooling flow controllers and predictive algorithms.

Energy savings: 18%, with enhanced product consistency.

Case 3: Specialty Chemical Producer – Waste Heat Reuse

A plant in Gujarat used reactor jacket outlet heat to preheat raw materials in the next batch, cutting down heating load by 15%.

Pioneering the Future of Efficient Reactor Design

At Liuminex Projects and Equipments Pvt. Ltd., we combine engineering expertise with sustainability to create next-generation reactors that meet the world’s most demanding process standards.

Our Key Energy-Efficient Features:

Precision jacketed and limpet coil reactors for optimized heat transfer

Custom automation and PLC-based control systems

Integration-ready for AI and IoT monitoring

Design compatibility with renewable and waste heat systems

Material optimization for thermal conductivity and corrosion resistance

Whether you operate in pharmaceuticals, agrochemicals, petrochemicals, or specialty chemicals, Liuminex designs each reactor with energy efficiency and safety at its core.

We don’t just build reactors —

we build smarter, greener, and more economical chemical processing systems for the future.

Shaping the Energy Future of Chemical Processing

Energy efficiency is no longer optional — it’s the foundation of modern reactor design.

By integrating smart controls, AI-driven optimization, renewable energy, and waste heat reuse, the chemical industry can dramatically reduce costs and carbon emissions while improving product quality and safety.

Liuminex stands at the forefront of this transformation, continuously innovating to provide sustainable reactor solutions that balance performance, safety, and efficiency.

In the decades ahead, the most successful plants will not be those that produce the most —

but those that produce most efficiently.