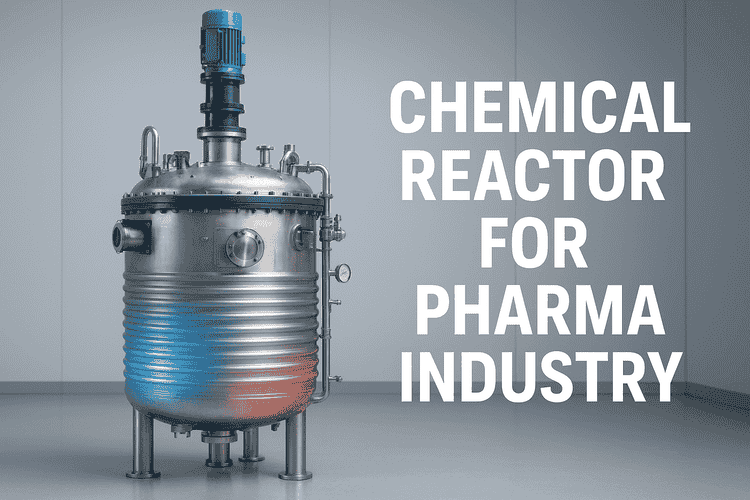

Reaction Vessels for Pharmaceutical API Manufacturing

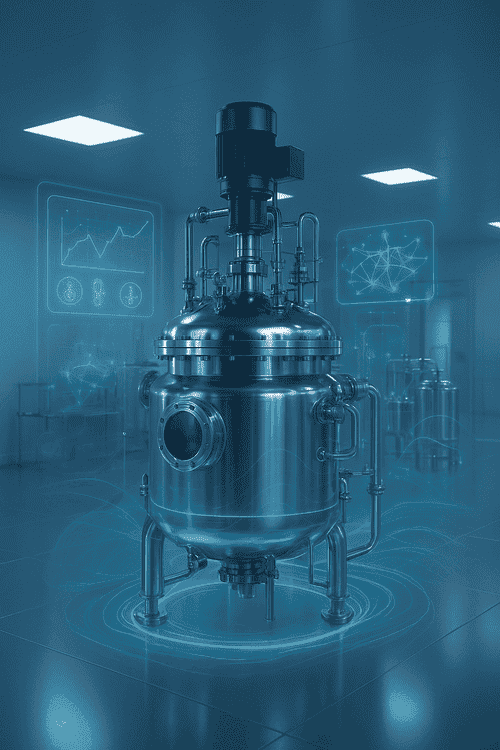

In the modern pharmaceutical industry, precision, safety, and efficiency are not just desirable—they are mandatory. At the heart of Active Pharmaceutical Ingredient (API) manufacturing lies one of the most critical pieces of equipment: the reaction vessel, also known as a chemical reactor.

These highly engineered vessels enable the controlled chemical reactions needed to produce APIs with the required purity, yield, and consistency. Whether it’s synthesizing a new antibiotic, formulating a cancer drug, or producing essential vitamins, reaction vessels are the workhorses behind pharmaceutical innovation.

In this comprehensive guide, we will explore the role of reaction vessels in pharmaceutical API manufacturing, the types used, their features, design considerations, and how to select the right one for your production needs.

Understanding APIs and Their Manufacturing Process

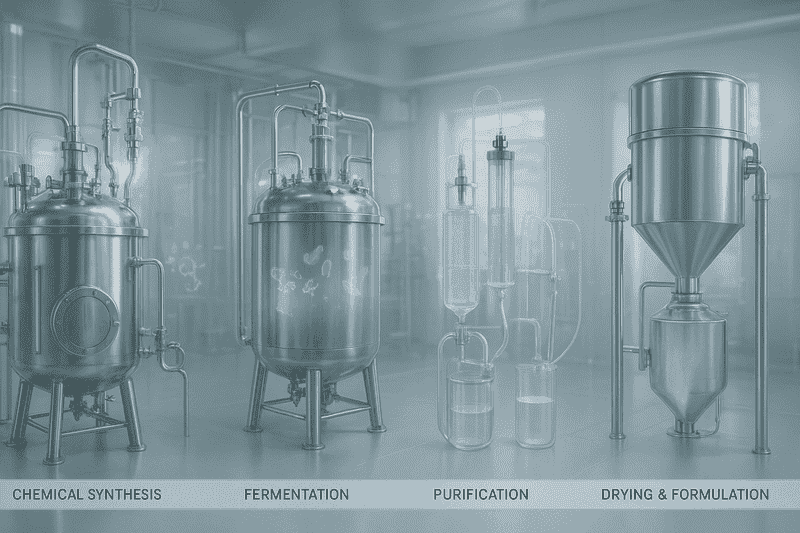

Active Pharmaceutical Ingredients (APIs) are the biologically active components in medicines. They are responsible for producing the intended therapeutic effect. API manufacturing involves a series of complex chemical and physical processes, such as:

Chemical synthesis – combining raw materials to produce the desired compound.

Fermentation – using microorganisms to generate active molecules.

Purification – removing unwanted by-products and impurities.

Drying and formulation – converting the API into a usable form for dosage manufacturing.

In many cases, chemical reactors are the first and most critical step in this chain, as they create the primary molecular structure of the API. Without precise control over reaction conditions, the yield and quality can be compromised, leading to costly waste or regulatory non-compliance.

Role of Reaction Vessels in API Manufacturing

Reaction vessels in pharmaceutical manufacturing act as enclosed environments where controlled chemical reactions take place. Their role includes:

Providing controlled reaction conditions (temperature, pressure, mixing speed).

Ensuring product safety by preventing contamination and exposure.

Withstanding corrosive chemicals often used in synthesis.

Meeting regulatory standards for cleanliness and material compatibility.

In the pharmaceutical sector, GMP-compliant chemical reactors are essential to ensure that every batch of API is consistent, safe, and traceable.

Types of Reaction Vessels Used in the Pharmaceutical Industry

Different pharmaceutical processes require different types of chemical reactors. Here are the most common types used for API manufacturing:

1. Stainless Steel Reactors (SS316, SS304)

Best for: Reactions where corrosion risk is low or moderate.

Advantages: High mechanical strength, excellent durability, good heat transfer.

Application: General chemical synthesis, solvent-based processes, and high-pressure reactions.

2. Jacketed Reactors

Best for: Processes requiring precise temperature control.

Advantages: Heating or cooling jackets enable controlled thermal exchange.

Application: Temperature-sensitive API synthesis such as peptide production.

3. Agitated Reactors

Best for: Processes that require uniform mixing and consistent reaction kinetics.

Advantages: Improved product consistency, better heat distribution.

Application: Emulsion-based pharmaceutical reactions and crystallization processes.

4. Glass-Lined Reactors (GLR)

Best for: Corrosive reactions involving acids, halogens, or other aggressive chemicals.

Advantages: Corrosion resistance, smooth and non-stick surface for easy cleaning, long service life.

Application: Production of antibiotics, vitamins, and specialty chemicals.

Key Features of Pharmaceutical-Grade Reaction Vessels

When designing or selecting a pharmaceutical chemical reactor, the following features are critical:

Material of Construction (MOC)

Stainless Steel 316L for hygiene and corrosion resistance.

Glass lining for acid-resistant applications.

Hastelloy or titanium for highly corrosive environments.

Surface Finish

- Mirror-polished or electropolished surfaces to reduce microbial growth and aid cleaning.

Agitation System

- Anchor, turbine, propeller, or contra-flow impellers based on the viscosity and mixing requirements.

Heating/Cooling Systems

- Steam jackets, hot oil, glycol systems, or thermic fluid for precise temperature control.

Pressure Rating

Low-pressure for standard reactions.

High-pressure and vacuum-rated vessels for advanced synthesis.

Automation

- PLC or SCADA integration for recipe-based operations and real-time monitoring.

Design Considerations for Pharmaceutical Reaction Vessels

Designing a chemical reactor for pharmaceutical manufacturing requires compliance with stringent regulations:

Capacity & Scale – from 50 liters for lab-scale to over 20,000 liters for commercial API production.

Regulatory Compliance – US FDA, EU GMP, WHO GMP, ISO certifications.

Ease of Cleaning – CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems are essential.

Containment – Proper sealing to prevent exposure to toxic or potent APIs.

Instrumentation – Pressure gauges, temperature sensors, and flow meters for control.

Advantages of Using High-Quality Reaction Vessels in API Manufacturing

Consistent Quality – Minimizes batch-to-batch variation.

Reduced Contamination Risk – GMP-compliant design prevents impurities.

Improved Heat Transfer – Ensures even temperature distribution.

Better Efficiency – Reduces reaction times and increases yield.

Long Service Life – Durable materials resist wear and corrosion.

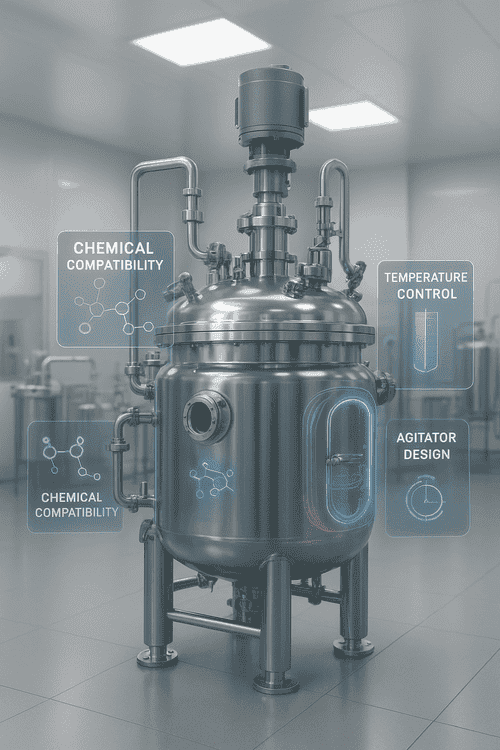

Common Challenges in Reaction Vessel Selection for Pharma Industry

Chemical Compatibility – Wrong MOC can cause corrosion or contamination.

Temperature Control – Inconsistent heating/cooling can affect product quality.

Cleaning Time – Long downtime between batches can hurt productivity.

Agitator Design – Poor mixing leads to incomplete reactions.

Case Studies: Reaction Vessel Applications in API Manufacturing

Case Study 1: Antibiotic API Production in a Glass-Lined Reactor

A pharmaceutical company manufacturing penicillin required a corrosion-resistant vessel. A glass-lined reactor ensured high purity, easy cleaning, and long-term durability.

Case Study 2: High-Potency API in a Stainless Steel Jacketed Reactor

For an oncology drug requiring precise thermal control, a jacketed SS316L reactor integrated with a PLC system delivered stable temperatures and ensured regulatory compliance.

Future Trends in Pharmaceutical Reaction Vessel Technology

IoT-Enabled Reactors – Real-time monitoring of reaction parameters.

AI Process Optimization – Predictive analytics for reaction control.

Energy-Efficient Systems – Reduced heating/cooling energy consumption.

Single-Use Reactors – For small-batch, high-value APIs to avoid cross-contamination.

The choice of reaction vessel can make or break a pharmaceutical API manufacturing process. Whether it’s a glass-lined reactor for corrosion resistance or a stainless steel jacketed reactor for precision control, the right equipment ensures safety, compliance, and profitability.

Investing in GMP-compliant chemical reactors not only boosts production efficiency but also ensures that patients receive medicines that meet the highest standards of quality.