"Understanding Types of Reaction Vessels and Their Industrial Applications"

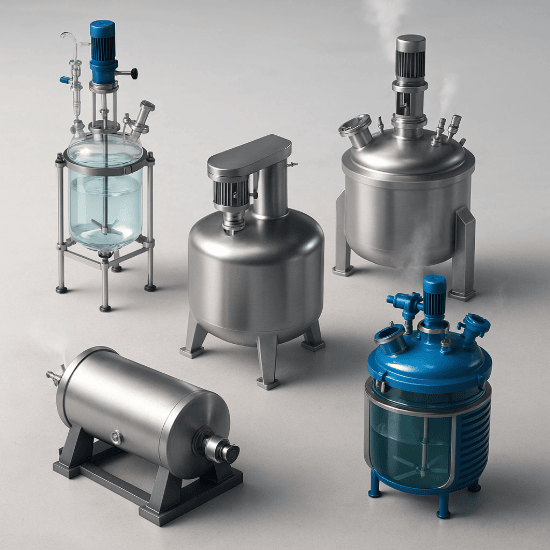

In chemical and process industries, the reaction vessel is the heart of any production setup. Whether synthesizing APIs in pharmaceuticals or manufacturing resins, dyes, or polymers, the type of reactor chosen directly impacts product yield, safety, and cost-efficiency. Understanding the various types of reaction vessels, their construction, and use-cases is crucial for selecting the best fit for your application.

This in-depth guide explores the most common types of reaction vessels, their benefits, construction materials, and typical industrial applications—helping engineers, plant heads, and project consultants make informed decisions.

1. What is a Reaction Vessel?

A reaction vessel (also called a chemical reactor) is a closed container designed to contain chemical reactions. It ensures that reaction conditions like temperature, pressure, agitation, and material flow are optimized and controlled.

Key Functions:

Containment of reactants/products

Heat transfer

Mixing/agitation

Pressure management

Product discharge or continuous flow

2. Primary Classifications of Reaction Vessels

There are many ways to categorize reaction vessels based on design, mode of operation, or construction materials. The two primary classifications are:

Based on Operation:

Batch Reactors

Most common in pharmaceuticals and specialty chemicals

Reaction takes place in discrete batches

Easy to clean, inspect, and customize

Continuous Flow Reactors

Ideal for large-volume production

Reactants continuously enter, and products exit

Requires advanced control systems

Semi-Batch Reactors

Combines elements of both batch and continuous

Reactants are added in stages during the reaction

Based on Heat Transfer Design:

Jacketed Reactors

Outer jacket for heating/cooling fluid

Used for moderate temperature control

Limpet Coil Reactors

External half-pipe coil for thermic fluid/steam

Handles higher pressures and temperatures

Common in resin and petrochemical plants

3. Types of Reaction Vessels by Construction Material

Choosing the right Material of Construction (MOC) depends on the chemical properties of the reactants and process conditions.

Stainless Steel Reaction Vessels

Grades: SS304, SS316, SS316L

Features: Corrosion-resistant, high strength, GMP-compliant

Applications: API synthesis, fine chemicals, food-grade processes

SS316L is especially suitable for aggressive chemical environments and is widely used in pharmaceutical reactors.

Glass-Lined Reactors

- Steel vessel lined internally with a chemically inert glass coating

Highly resistant to acids, halogens, and corrosive solvents

Easy to clean and inspect

- Ideal For:

Acidic reactions

Fine chemicals

Dye and pigment manufacturing

Multistep reactions

- Note: Avoid using glass-lined vessels for processes with strong alkalis or sudden temperature shocks.

MS (Mild Steel) Vessels with Rubber/FRP Lining

Cost-effective for non-corrosive or moderately corrosive applications

Often used in fertilizer, polymer, and water treatment sectors

Limitations:

Lower lifespan

Not suitable for precision reactions or GMP plants

Hastelloy, Titanium & Exotic Alloy Vessels

Used for extremely corrosive processes (e.g., nitric acid, sulfuric acid at high temperature)

High initial cost, but long-term reliability

Used in:

Agrochemicals

Explosive intermediates

Chlorinated solvent-based processes

4. Types of Reaction Vessels Based on Mixing Mechanism

Proper agitation is essential to ensure heat and mass transfer within the reactor. The vessel design varies accordingly.

Anchor Type Agitated Reactor

Ideal for high-viscosity materials

Common in polymerization and resin synthesis

Includes baffles to eliminate vortex formation

Turbine Agitator Reactors

Suitable for low-viscosity fluids and rapid blending

Provides radial flow and enhanced turbulence

Often used in aqueous solutions and neutralizations

Contra-Rotating Agitator Vessels

Two impellers rotating in opposite directions

Provides uniform shear and mixing

Perfect for emulsions, dispersions, and exothermic reactions

Magnetic Stirred Reactors

No mechanical seals—ideal for sterile/GMP applications

Used in biotech and pharma fermentation systems

5. Specialized Types of Reaction Vessels

Autoclaves / High-Pressure Reactors

- Designed for high-pressure, high-temperature synthesis (hydrogenation, polymerization)

Often constructed from SS316 or Inconel

Comes with safety interlocks and rupture discs

Rotary Vacuum Reactors (RVPD)

Combines mixing, heating, and drying in a vacuum

Widely used for solvent recovery and drying APIs

Reduces drying time and improves purity

Jacketed Glass Reactors (Lab Scale)

Used for pilot and R&D operations

Visual monitoring of reaction

Comes with reflux condenser, dosing funnel, and temperature probe

6. Applications of Reaction Vessels in Industries

Each industry has its own set of requirements. Here’s how different sectors apply various types of reactors:

| Industry | Common Vessel Type | Key Considerations |

|---|---|---|

| Pharmaceuticals | SS316L Jacketed, Glass-lined | GMP compliance, sterile design, CIP system |

| Agrochemicals | Limpet coil SS316, MS vessels | Exothermic control, corrosion resistance |

| Polymers/Resins | Contra agitator, Limpet coil | High-viscosity handling, high-temp capability |

| Dyes & Pigments | Glass-lined, MS-Rubber lined | Acid resistance, color stability |

| Food & Flavors | SS316 jacketed with anchor mixer | Sanitary design, temperature control |

| Specialty Chemicals | Hastelloy, Glass-lined vessels | Multi-step reactions, pressure handling |

7. Key Design Considerations When Choosing a Reaction Vessel

To select the right type of reactor, consider the following:

-

Chemical Compatibility: Use chemical compatibility charts with MOC options.

-

Reaction Type: Exothermic vs endothermic determines jacket/coil requirement.

-

Pressure & Temperature: Specify max operating limits and build safety margins.

-

Scale & Volume: Always plan for 10–20% buffer over working volume.

-

Cleaning Requirements: CIP vs manual, GMP mandates, internal polish level.

-

Safety Features: PRV, rupture discs, interlocks, insulation, grounding.

-

Automation Needs: DCS/PLC support, instrumentation, SCADA-ready.

8. Common Mistakes to Avoid

Using SS304 where SS316L is needed (leads to corrosion).

Undersizing jackets or coils for heat transfer.

Ignoring future process scale-up needs.

Installing vessels without proper agitation analysis.

Not considering cleaning/accessibility for GMP processes.

Choosing the correct type of reaction vessel is more than a purchase—it’s an investment in the safety, efficiency, and scalability of your chemical processing plant. By understanding the differences between vessel types and their applications, engineers and plant managers can ensure optimal production performance and regulatory compliance.

At Liuminex Projects and Equipments Pvt. Ltd., we specialize in designing and manufacturing reaction vessels tailored to your unique chemical processes—from GMP-certified pharmaceutical reactors to high-performance resin vessels.