Industrial Storage Tanks

High-Quality Industrial Storage Tanks for Chemicals, Oils, and Liquids

At Liuminex, we specialize in the design and fabrication of high-quality industrial storage tanks for chemical, pharmaceutical, oil & gas, food, lube oil, paint, and water treatment industries. Our tanks are engineered to provide safe, corrosion-resistant, and long-term storage of liquids, chemicals, solvents, and oils under atmospheric or pressurized conditions.

We offer custom capacities, shapes, and materials, and build to IS, ASME, and GMP standards.

Types of Storage Tanks We Manufacture

1. Vertical Storage Tanks

- Space-saving design

- Ideal for liquid raw materials, water, and solvents

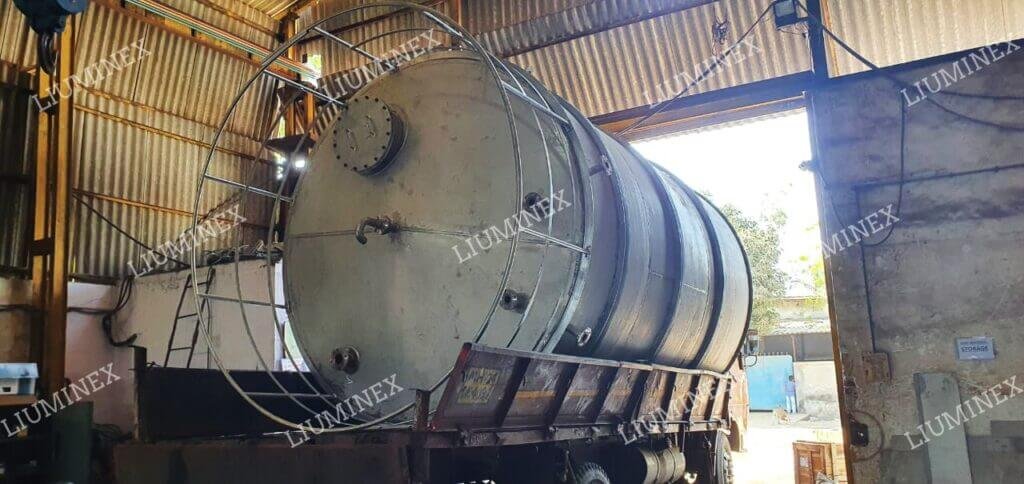

2. Horizontal Storage Tanks

- Suitable for skid-mounted systems or under pipelines

3. Underground Storage Tanks (UST)

- For fuel, diesel, and chemical storage with anti-corrosion coating

4. Jacketed Storage Tanks

- With steam/oil jackets for temperature control (optional insulation)

5. Pressure Storage Tanks

- Built to handle high-pressure containment of gases and reactive liquids

6. Agitated Storage Tanks

- With stirrers for mixing or homogenizing during storage

Technical Specifications

Parameter | Specification |

Capacity Range | 500 Litres – 100,000 Litres |

Design Pressure | Up to 15 bar (for pressurized models) |

Material Options | SS 304, SS 316, Mild Steel, FRP-lined, Hastelloy |

Tank Orientation | Vertical / Horizontal / Skid-mounted |

Surface Finish | Mirror / Matt / Pickled / Epoxy Coated |

Manways & Nozzles | Custom size with flanged ends, as per drawing |

Level Monitoring | Sight glass / Radar type / Float type (optional) |

Insulation | Rockwool / Glass wool with aluminum cladding |

Key Features

- Leak-proof, welded construction

- Corrosion-resistant materials and coatings

- Available with agitators, level indicators, CIP/SIP ports

- Designed as per API / IS / ASME standards

- Can be delivered skid-mounted with piping and valves

- MSRL / FRP lining for aggressive chemicals

Applications

- Lube oil and grease storage

- Solvent and chemical storage

- Water and effluent treatment plants

- Intermediate bulk liquid storage

- Paint and resin blending tanks

- Diesel and fuel tank systems

Working Principle and Design Philosophy

At the heart of every industrial storage tank lies a careful balance between mechanical strength, corrosion protection, and operational efficiency.

Liuminex follows a structured design philosophy based on the latest IS, ASME, and API standards, focusing on:

Uniform wall thickness and stress distribution,

Adequate venting and overflow arrangements,

Corrosion allowance for long-term durability,

Proper nozzle orientation for easy integration with process lines.

Our design team uses advanced CAD and finite element analysis (FEA) tools to simulate stress, pressure, and thermal loads — ensuring that each tank is both safe and efficient for your specific application.

Construction Materials and Coatings

We understand that every industry handles different types of materials — and that’s why Liuminex offers a complete range of material options and protective linings for your storage tanks.

Common material configurations include:

Stainless Steel (SS 304 / SS 316): Ideal for food, pharmaceutical, and chemical storage requiring hygiene and corrosion resistance.

Mild Steel (MS): Economical option for non-corrosive fluids, often paired with internal coatings.

MSRL (Mild Steel Rubber Lined) & FRP Lined: For acids, alkalis, and aggressive chemicals.

Special Alloys (Hastelloy, Inconel): For high-temperature or highly corrosive environments.

Each tank can be internally coated with epoxy, rubber, or FRP linings depending on the chemical compatibility. External coatings ensure long-term resistance to weather, humidity, and UV exposure.

Why Choose Liuminex as Your Industrial Storage Tank Manufacturer in Mumbai

As one of the most trusted industrial storage tank manufacturers in Mumbai, Liuminex is known for its precision engineering, superior material selection, and commitment to safety. Our tanks are custom-built to handle a wide range of liquids — from corrosive chemicals and flammable solvents to edible oils and water-based solutions.

Each tank is designed after a detailed process analysis, ensuring complete compatibility with the stored medium and the plant’s operational environment. Whether it’s a compact SS storage tank for laboratory use or a 100,000-litre industrial chemical tank for large-scale operations, we deliver systems that perform reliably under the most demanding conditions.

Manufacturing Excellence and Quality Assurance

Every tank fabricated at Liuminex undergoes rigorous inspection and testing protocols, including:

Hydrostatic and pneumatic pressure testing,

Dye penetration and weld inspection,

Radiographic and ultrasonic testing (as required),

Dimensional and surface finish verification.

Our quality system ensures compliance with GMP, ISO, and ASME standards, and every tank is accompanied by full documentation — material test certificates, inspection reports, and drawings for customer validation.

Customization Capabilities

One of Liuminex’s biggest strengths as a chemical storage tank manufacturer is our ability to tailor every design to specific client needs. We offer complete customization in:

Tank size and geometry (cylindrical, rectangular, conical, or vertical orientation)

Heating/cooling jackets and insulation systems

Level monitoring and automation integration (float, radar, or digital sensors)

Agitator or mixer installation for process blending

Skid-mounted assemblies with piping, valves, and instrumentation

Manways, nozzles, and drain arrangements as per process layout

Whether your requirement is a pressure-rated vessel, a mobile storage tank, or a double-walled containment system, our engineering team delivers precise and compliant solutions.

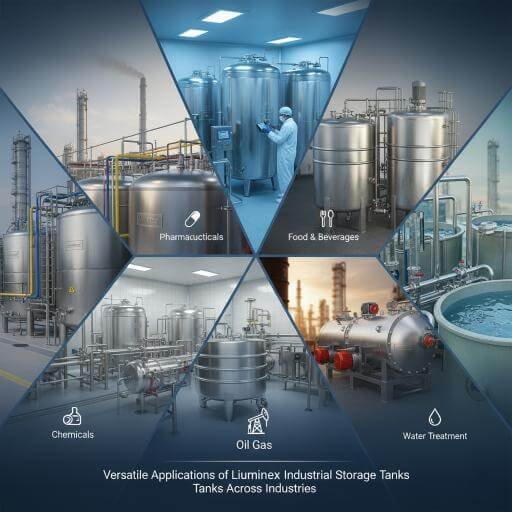

Applications Across Industries

Liuminex industrial storage tanks serve diverse applications across process industries:

| Industry | Common Usage |

|---|---|

| Chemical & Petrochemical | Storage of acids, solvents, catalysts, and intermediates |

| Pharmaceutical & Nutraceutical | Sterile water, liquid formulations, and APIs |

| Food & Beverage | Edible oil, sugar syrup, milk, and flavor storage |

| Lubricants & Greases | Lube oil, hydraulic fluids, and base oil blending |

| Paints & Coatings | Resin, pigment, and solvent storage |

| Water Treatment | Raw water, effluent, and RO plant tanks |

| Oil & Gas | Diesel, fuel oil, and process condensate storage |

Each system is designed to ensure leak-free, contamination-free, and temperature-stable operation.

Benefits of Liuminex Industrial Storage Tanks

✅ Superior Durability: Designed for long operational life with minimal maintenance.

✅ Corrosion Resistance: Use of high-grade SS and protective linings to ensure longevity.

✅ Enhanced Safety: Compliance with global pressure and design codes for operator and plant safety.

✅ Customization Flexibility: Fully engineered to integrate with your process flow.

✅ Ease of Cleaning: Optional CIP/SIP (Clean-in-Place / Steam-in-Place) systems.

✅ Energy Efficiency: Options for thermal insulation and jacketed heating reduce operational losses.

These benefits make Liuminex a preferred industrial tank supplier in Mumbai and a trusted partner across India’s process manufacturing sector.

Integration and Automation Options

To support smart manufacturing and Industry 4.0 practices, Liuminex offers automation-ready tank systems.

Our storage tanks can be integrated with:

PLC/SCADA-based monitoring for level, pressure, and temperature,

Automatic filling and discharge valves,

Load-cell-based batching systems,

Remote data logging and control interfaces.

This ensures accurate material management and improved plant efficiency — ideal for chemical, pharma, and oil processing facilities.

Sustainability and Environmental Responsibility

Liuminex designs its tanks with sustainability in mind. We minimize material waste during fabrication, use eco-friendly coatings, and provide double-containment options for hazardous materials. Our industrial storage tanks are engineered to meet both safety and environmental regulations, reducing risks of leakage or contamination.

Why Liuminex Is the Preferred Industrial Storage Tank Manufacturer in India

From design to dispatch, Liuminex combines engineering excellence, material expertise, and customer-first service. Our industrial tanks are installed across India and abroad, earning us a reputation for reliability, customization, and safety.

Whether you need a single SS storage tank or a fully integrated chemical storage system, Liuminex delivers solutions that help optimize your production efficiency and ensure long-term performance.